Hello to all Datagorians! After a short break, I decided to continue my research into making acoustics at home. Let me remind you of my first experience: building active computer speakers based on Sven SPS-608 and Hertz DCX 690 car speakers. This time I decided to do something more “serious”. The idea remained unchanged, i.e. minimum costs, and maximum use of available and available materials. TQWP format speakers

.

Tapered Quarter Wave Pipes by me

↑ Idea

What was available was almost all the necessary tools, and that was already half the battle. There was also a Soundmax SM-CSM62 car speaker, practically new

I understand that experienced people will say that it’s car acoustics again, but you can’t build anything worthwhile on it, etc., well, that’s okay, so to speak, we’ll learn from our mistakes, so that it would be easier later, and getting better at building is worth a lot.

The appearance was chosen initially and was not discussed. Vertical narrow and tall floor-standing speakers. In terms of all acoustic parameters (and, as it turned out, they are practically the same for mid-budget 16.5 cm acoustics), it was supposed to be made as a 3D, which is more favorable for car acoustics, and is also easier to manufacture. We ordered chipboard panels from a friend measuring 1200x200x200 mm, which in total would give approximately 40 liters. pure internal volume, which, if necessary, could be filled with something to reduce it.

But we are not looking for easy ways. Scrolling through the Internet once again, I came across an article on the description and production of TQWP. The decision was made and the process began. The speakers were also built for the future, with the possibility of further upgrades to replace the acoustics. The calculation was carried out in the program of the same name

Calculation and drawing of TQWP speakers

Since it was not possible to find any vehicle parameters for this acoustics, and only one speaker’s own resonant frequency (Fs) was needed for the calculation, a bunch of information was dug through on 16.5 cm car acoustics with similar designs and diffuser materials, and it was experimentally established that Fs on average varies from 50 to 80 Hz. 60 Hz was selected. A small error in the choice of Fs, by and large, did not lead to any significant deviations in the calculation of the program.

Sketches of TQWP drawings

After you have entered all the required parameters for the materials required to build the body, you can print sketches of the drawings by clicking the “ Print sketches ” button. 8 sheets of A4 format will be printed indicating the dimensions. Unfortunately the sketches are not to scale.

It should be noted that the grill sketch will be printed in 2 versions, for one speaker and for two (including HF). Choose which one you like best.

Rice. 4. Sketches of TQWP drawings

↑ Assembly stages

Because

Initially, panels with a height of 1200 mm were ordered; later, a partition had to be installed on top to adjust to the calculated dimensions. Just in the upper box there is a crossover and a tweeter. The process of cutting holes for the speakers and further fitting, as well as all primary assembly, was carried out in the garage. Final assembly was done at home. Here are some steps

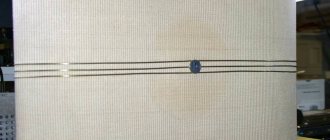

All joints were glued with Moment glue and the screed with 3.5x30 mm screws. Partially, the front and rear walls were glued from the inside with automotive sound and vibration insulation, left over from old scraps. At the same time, for convenience, a filler was attached - 300 padding polyester. The filler is used approximately 70-80% of the total volume.

Well, as it turned out, the most labor-intensive process is covering it with carpet.

The speakers themselves are installed on homemade stands that stand on furniture legs-spacers.This is what it looks like when finished

And on the spot

Formulas used in calculating TQWP

Rice.

2. Formulas used in calculating TQWP The TQWP calculation table deliberately contains inaccuracies compared to the original file. The question is, what is considered the open end of the horn, the bottom of the cabinet, or the distance from the top of the port to the back wall?

In my opinion, the port is not part of the resonator. Although this is my personal opinion. I could be wrong. According to David B. Weems calculations, the actual horn length may be 20% longer than the calculated length, so even if I'm wrong, the error is still within acceptable limits.

↑ Sound

For now, this speaker is being listened to on the ancient Panasonic SC-CH75GC-K MC, which has been serving faithfully since back in 1996. To be honest, I’m very pleased with the sound.

There is not the slightest hint of muttering. There is a very nice soft bass. In general, the sound is very pleasant and quite assertive. The test disk showed that the low end was from 40 Hz, but clearly audible from 50 Hz. In reality, in music I think somewhere between 55-60 Hz. Although the windows begin to clink and give off a chest-like sound at 50% volume in a room of 18 m2. I liked the sound of Jazz, both vocal and orchestral. All Metal played with a bang. I especially liked Stoner Metal/Rock, with its viscous low guitar riffs. Thank you all for your attention.

Don't be afraid to start and make mistakes. All comes with experience.

Gallery TQWP

So, we are building an acoustic system for the home.

Choosing a concept is very difficult. One speaker or three, active acoustics with complex amplifiers, simple amplifiers with complex filters in Acoustic systems.

You just need to decide for yourself what will seem better when listening. Today it is difficult to say which is better. However, I no longer have any doubts - Acoustics must radiate a range from 150 to 7000 Hz from one point, otherwise stereo will be very conditional. I can’t save up for Martin-Logan electrostatics, and therefore the only way is speakers on a full-range speaker.

Listening to various speakers at the NOEMA factory gave me a reason to choose a design option for the bass - only OJ J and no compression. Only large-sized speakers with rigid suspension, highly sensitive and with a small diaphragm stroke, and only paper diffusers - no plastic.

Why? - this is a separate story - there is no esotericism here - solid physics and mathematics...

Speaker selection.

In Soviet times, the industry produced quite good speakers - 4A32. This is a 12 inch full range speaker. But finding such a speaker in good condition is very difficult. Moreover, in order to use this speaker as a basis for building your own high-quality speakers, it needs to be greatly improved.

There is a “Gorynych” method for refining these speakers. But still, these speakers, even after all the improvements, will not be ideal for a real broadband link. But finding a real pair of 4A32 with an ALNICO magnet in excellent condition is now almost impossible. A long search for a suitable speaker led me to the Novosibirsk NOEM plant.

This company produces equipment for the professional audio market. They release the 75GDSH-3-3 speaker. This is a continuation of the 4A32 line. During the operation and production of wideband speakers, 75GDSH-3-3 was an almost perfected J version of the 4A32. The moving system (Diffuser, suspension, centering washer) has been completely improved.

Firstly, the shape of the woofer diffuser is made in the form of a sector of a circle, and not a simple cone, like the 4A32.

Secondly, there are anti-diffraction rings on the diffuser, which increases the rigidity of the diffuser and prevents “spot radiation” at high volumes (seemingly the effect of zonal radiation) by switching the diffuser to ring mode - i.e.

with increasing frequency, the radiation zone decreases more and more J, gradually, at high frequencies, approaching the coil. The shape of the HF horn ensures HF reproduction up to 16000Hz (-5dB) and virtually no such nasty resonance at 2500Hz for many wideband speakers.

Technical problems with the preparation of paper pulp for the manufacture of diffusers have been completely resolved - as a result, the speakers have very repeatable characteristics. Rag sinusoidal suspension, the necessary impregnation of the diffuser has been carried out.

Overall, considering the cost, these speakers can be very attractive to DIYers. Now let's listen to how it sounds in the author's version. When I came to NOEM, I was determined to buy HF 10GDV-92, and 35GDN-62 for the manufacture of FI ASok. But after listening to the sound of the 75GDSH-3-3 in a standard factory box, everything disappeared.

Natural, live Vocals. Beautiful guitar, clear and elastic Drum. In general, the speaker showed itself to be excellent. And now, two speakers on the execution table......

TKuVT requires a speaker with high Qts. 16 The ohm version 75GDSH-3-3 has the required parameters and here it is and its frequency response. In comparison with the frequency response of 75GDSH-3-1.

- for more details on the speakers, visit the NOEMA website

- Since the lower limit frequency of these speakers is approximately 47Hz, the frequency response….

It is necessary to increase the output of the speakers at lower frequencies in order to compensate for the drop in the frequency response of the speaker below 55Hz... Using the Housing in the exponential horn version for this size....the dimensions of my apartment did not allow.

And my choice settled on the Quarter-Wave Resonator of Reverse Radiation. This housing option provides sufficient gain for a fairly narrow frequency band in the tuning zone, while having fairly acceptable dimensions. TQWP, or Voight pipe.

First described by Paul Voigt in 1930, TQWT offers a good quality-price ratio.

They are also easy to make yourself. Very close to transmission lines, TQWT is distinguished by its waveguide shape. A kind of horn is used as a return load for the cone, but the speaker is not placed at the beginning of the horn as usual, but on its side.

The port is used to utilize airflow from the back of the speaker cone to provide internal damping and increase bass response. The resonance frequency depends only on the length L of the cone, and the position of the speaker, calculated according to the formula indicated in the diagram.

There is a program to calculate the “collapsed” version of this AC box.

The biggest questions are the troat depth parameter (the depth of the horn neck, it is not recommended to make it more than 1-2 inches) and the surround width - the width of the ring around the diffuser - essentially the mounting area for the diffuser basket housing.

Everything else seems clear. Theoretically, it doesn’t matter which side the speaker is located on, but I wouldn’t place the port against the wall.

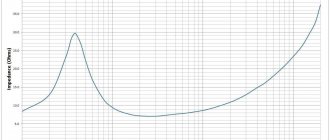

Since any pipe or horn is essentially a “comb” resonator ;), the resulting frequency response will look something like this:

Where the frequency response curve of the head itself is indicated in blue, and in red is what will sound from the speaker port. Isn't it a beautiful spectacle?

- If we further simulate the overall frequency response of the system, we get a very beautiful picture:

To the ear - this very resonance at 215 Hz = a very booming soloist and the trumpet is so pioneering... in general, a terrible sound with a clear “boxy” and gunky sound..... In order to avoid this defect, we need to cut off and muffle all resonance peaks except the first .

This is done with the help of highly effective sound-absorbing fillers, which fill part of the speaker cabinet.

You can also try Ursa mineral wool (just not our glass wool - it’s life-threatening!!!), viscose or natural wool, Holofiber or some other padding polyester, I was pleased to find information about especially thin basalt fiber, which is labeled BSTV (Basalt Super Thin Fiber) is sold in building supply stores. This is an environmentally friendly material with excellent sound-absorbing properties. Thus, we need a mat with a thickness of only 10 cm to very deeply suppress all resonance peaks except the first one, the suppression coefficient of which is very small. In addition, such filling “virtually” increases the length of the horn and thereby tunes the Box to a lower return frequency.

As a result, the resulting AC curve will look something like this - and although there are fractures in the frequency response on the line as a result of incomplete suppression of the saw, in reality they are very small. The only thing is that you can’t overdo it in any way - excessively filling the speaker cabinet with absorber will also lead to suffocation of the bass :).

Calculated housing dimensions for speakers on 75GDSh-3-3.

These dimensions are made for a multilayer housing. The inner layer is bakelite plywood, which has the highest rigidity, and the outer layer is chipboard (between them there is glue and rubber-bitumen mastic). You can also understand the location of the reinforcing (internal) panels :).

During the adjustment process, it is a good idea to leave one side of the housing completely closed (easier the back) so that you can easily change the internal cotton padding to find the optimal damping.

Next comes the fun part - making the case.

There is a large amount of material on the Internet on the selection of materials and manufacturing technologies for precast panels that provide high rigidity and acoustic impermeability.

My choice was made as follows - the front panel is prefabricated. The base is solid pine, 20mm thick, then we coat the inside of the wall with vibration-absorbing rubber-bitumen automotive mastic. Next, 10 mm bakelite plywood for liquid nails (it’s terrible how rare and expensive this plywood is - I only managed to find one sheet L).

This sandwich is pulled together with self-tapping screws, fortunately there is a good drill and impact wrench. Next – Felt 15mm. On the side that will be glued to the plywood, I impregnated 3-5mm of felt with the same mastic and glued it to the same liquid nails J. The body with such dimensions must be made very durable.

Broadband speaker for 10 GDSh-1

The loudspeaker head 10GDSh-1 (10GD-36K) was developed more than 20 years ago at VNIIRPA named after. A.S. Popov and for many years has been produced by the Acoustics plant in Znamenka (Ukraine).

It is intended for use in single-way speakers, which are cheaper and simpler than two- and three-way speakers and have less phase distortion due to the absence of crossover filters. The 10GDSH-1 head alone is capable of reproducing almost the entire audio frequency range.

Effective operation in the low-frequency region is ensured by the use of a special flexible suspension made of polyurethane foam and a rigid diffuser with a curved generatrix, and in the high-frequency region - by a second diffuser.

The use of these heads in small-sized speakers such as 15AS-223 and the like with an internal volume of about 14 liters does not make it possible to fully realize the capabilities of the 10GDSh-1 in the region of the lowest frequencies. Figure 1 (curve 1) shows a typical frequency response of 15AS-223 in the frequency range up to 250 Hz.

At frequencies above 80 Hz, the frequency response is almost linear (“piston” range of this type of head extends to 400-500 Hz and above), below the frequency of 75 Hz (-3 dB) there is a steep decline, reaching -12 dB at a frequency of 50 Hz.

The table shows the parameters of several 10GDSh-1 heads (columns “V=∞”), as well as heads in a housing with a volume of 60 l, calculated from the condition of obtaining a total quality factor of the system less than one (columns “V=60 l”). The spread of parameters turned out to be not large; the values of Qп (“V=∞”) are on average within the range of 0.7-0.8, i.e. the calculated volume of the AC is 3-4 times greater than Ve.