How does information recorded on a disc turn into wonderful sound?

Save and read later -

Have you ever peered into the surface of a vinyl disc and wondered how that tiny groove produces powerful sound in your speakers? If yes, then you have come to the right place.

The idea itself was born about 140 years ago with Edison's phonograph, but modern technology is about half as old. Columbia Records released the first 12-inch long-playing record in 1948; The first public demonstration took place on June 20 at the Waldorf-Astoria Hotel in New York. The rest, as they say, is history.

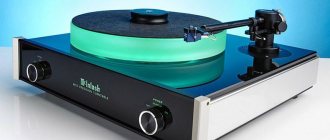

Vinyl as a format seems practically immortal. It is a marvelous piece of engineering that looks incredible even today. Nevertheless, it works, and with the right selection of equipment, even great.

Whether you, our reader, are an experienced vinyl disc collector or a neophyte about to buy your first turntable, a little new knowledge will not hurt you.

Groove

On one side of the record there is one groove, which runs in a spiral from the edge to the center and is approximately 0.04–0.08 millimeters wide (depending on the signal level). If you expand the groove of a 12-inch disk, it will stretch almost 500 meters.

The two sides of the groove are at right angles to each other, with the apex pointing downwards. Each of them is dotted with “convolutions” that carry information for both stereo channels.

The right signal is recorded on the side closest to the outside of the disc. This information can be stored in a space as small as a micron (one thousandth of a millimeter), so retrieving it is a daunting task.

This circumstance also explains the sensitivity of vinyl players to external vibrations and other interference.

About modification and repair of vinyl players

I recently met an interesting man, 67 years old. The man is very fond of vinyl music and has many different players - from Arcturus-006 to Fine ARTS TD-903 from Grundig. However, all the players work poorly or don’t work at all, because they are only a little less old than this man himself. And he brings me all these players for repair and hopes that I will return them to a second youth. I try my best, because the person is a good person, and I myself am interested. During the renovation process, of course, you have to surf a lot on “your” Internet and sometimes read surprising and unexpected things.

So, for example, on one forum there is a very serious discussion about the benefits of weighing down the disk of a player, one that is iron and on which the record itself is directly placed. Like, to reduce rotation speed instability. One specialist writes about his experiments like this:

“I put on the disk of my player, for weighting, a disk from a dumbbell weighing 1 kg. The disc was spinning as if nothing had happened, nothing had changed in the world. Then I put another such disc in and the player could not start on its own. But I helped him with my hands and he started spinning again. I don’t know how this affected the sound quality, because the height of all these discs became such that it was impossible to lift the tonearm onto the record! Then I decided to just continue the experiment and put in another 3 kg disc (we had all run out of kilogram ones). I spun it again by hand and the whole thing spun and spun for a while quite well and, I think, quite stably due to the large inertial moment. But then there was a burning smell and smoke came out of the player, damn it - the engine burned out... Based on the experiment performed, we can conclude that, probably, the maximum weight of the disc is somewhere between two and five kilograms. I'm going to buy a new engine, does anyone have one? I want to determine the maximum possible weight of a disk with higher accuracy..."

So, a friend of mine brought in a 1985 Arcturus-006 turntable for repair, whose disk suddenly stopped starting and spinning. He said that he removed the disk to troubleshoot and... did not find the engine itself, not even any roller belts! The man was very puzzled by this state of affairs, because he had lived in this world for 67 years and seen everything, but this... He asked if the engine could have burned to the ground, that is, completely without a trace? I expressed doubts about this and we began to figure it out. They removed the disk and indeed, they did not even find traces of any engine.

This is understandable to me, because here is just an original low-speed motor, where the rotor is the player disk itself with a magnetic tape glued on it. However, before explaining this fact to the person, I decided to first draw his attention to the large number of dead cockroaches in the cavities of the case under the disk. I said that this is a unique player with an experimental biological engine, very economical and does not cause any harm to the environment. And the driving force is precisely the cockroaches, subjected to special training in the Polish biological laboratory. When the power is turned on, a current discharge is supplied to the cockroaches, they get angry, swear and begin to spin the disk out of frustration - but where should they go?! But nothing lasts forever under the sun, not even cockroaches. So they all died, and now there was no one to spin the disk...

Then, of course, he took pity on the man, stopped telling fairy tales and repaired his record player. Several years have passed since then, and Arcturus-006 is still playing. But I assume in advance that he will soon die again and am currently training a new batch of cockroaches :-))

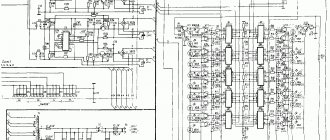

Even in this Arcturus, my imagination was struck by a preamplifier-corrector that looked like this:

The board seems clearly too small for such capacitors. Although I may not be an ardent audiophile at all and I don’t understand what a beautiful, transparent, detailed sound is produced by capacitors of this size. Some will say that for particularly high-quality and natural sound, even such condensers are perhaps too small! Moreover, if you also load the disc with “pancakes” from the barbell by 25 kilograms? Of course, the result will be a truly divine sound! Just how many specially trained cockroaches will you need? Author: Andrey Baryshev.

Cartridge

The job of the cartridge - or cartridge head - is to pick up information from the groove, or more precisely, the function of the stylus.

The needle is made of a very hard substance, usually diamond. But don't get too excited - this is an industrial diamond, not a gemstone. Compared to treasures from a jewelry store, it lacks cleanliness.

The very thin tip of the diamond needle (available in different shapes) moves along the groove and follows all its twists as the disc rotates.

The pattern and degree of vibration of the needle is converted into the frequency and amplitude of the signal, which you then hear through the speakers. They are transmitted through the cantilever or stylus holder - the lever to which the stylus is attached - to the body of the pickup head.

Moving magnet cartridge circuit diagram

Moving coil cartridge circuit

There are two types of cartridges: moving magnet and moving coil. The operating principle of both is based on the phenomenon of electromagnetic induction, the essence of which is that the movement of a conductor in a magnetic field leads to the induction of current.

As is easy to understand from the name, in one type of head a magnet moves to create a current, in the second there is a coil, and the magnet is fixed. So, if we are talking about a moving magnet cartridge, it has a tiny magnet attached to the hidden end of the needle holder; Due to the movement of the needle tip, it also moves.

Changes in the magnetic field cause an electric current in tiny coils located nearby; this signal is output to the back of the cartridge and fed to the amplifier. If it only accepts a line level signal, as is often the case, then you need a special phono stage.

How to Build Your Own DIY Vinyl Record Player

Weekend Workshop: Become a hipster and build this DIY vinyl record player

Need something to keep you busy this weekend? Look no further. Weekend Workshop is our weekly feature where we showcase a cool DIY project that you can complete with minimal skill and experience. We've scoured all the online tutorials on the Internet and gone the extra mile to identify projects that are equal parts easy, accessible, and fun. So put on your work pants, grab your tool belt and head out to the garage - it's time to start building!

As any baby boomer or bearded guy in a plaid shirt will tell you, vinyl records are the only way to listen to music. Whether it's the (disputed) fact that vinyl records sound better, or the simple desire to physically own an album as opposed to downloading a streaming service, vinyl has increased its popularity significantly over the past few years. It's not hard to see the charm either. Being able to sift through your music drawer while searching for the perfect Saturday morning tunes is much better than clicking the magnifying glass on Apple Music—for some, at least.

Considering the fact that this appeal has spread like wildfire, simply buying a turntable (used or new) does little to express your individuality. But what if you made your own? This is exactly what Instructables user Mikeshorr117 did and the finished product is great. With some plywood, a few 9V batteries and a small set of speakers, this experienced DIYer created a completely original turntable that even the hippest audiophile couldn't own.

mikeshorr117/Instructables

To help you get started on building your own unique DIY turntable, we've scoured Mikeshorr117's build list to piece together an accurate index of what's needed for the project. While this build opted for a simple exterior box design, Mikeshor117 says any changes or additions are left to the developer's discretion. Just make sure there is enough space in the column for the speakers, motor and amplifier, otherwise the rest of the walkthrough will be difficult to complete. Here's what you need to get started:

What size is a vinyl record?

Actual size

A 12"

record

is 302mm (11.89"), a 10" record is 250mm (9.84"), and a 7" record is 175mm (6.89").

If you buy records

made in different countries, you will notice that their manufacturers adhere to different guidelines.

Interesting materials:

Where does Plasmodium falciparum reproduce? Where is a traffic stop permitted? Where is it allowed to stop in the city during the exam? Where to register a car at the place of registration? Where to register a car purchase and sale agreement? Where was Albert Einstein born? Where was Davidich born? Where was Nikolai Karachentsov born? Where is Russia building nuclear power plants? Where is Russia building nuclear power plants?

Let's isolate ourselves

As we have said more than once, a vinyl player is very dependent on the world around it. Through the stylus, the pickup converts any mechanical vibrations into an electrical signal, and these vibrations can be caused not only by the modulation of the sound track of the record, but also by any external influences. In other words, in order for the player to produce only a music signal, it must be isolated from external mechanical influences.

For this reason, the best option for installing a turntable would be a shelf mounted in the room on a permanent (external) wall. Custom shelving isn't cheap, but it's a long-term investment that's worth making. It is necessary to choose a specific model based on its load capacity and dimensions, which must correspond to the corresponding parameters of the existing player. If for some reason placing a wall shelf in the living room is not suitable for you, then we can offer another option from the “cheap and cheerful” series for installing a record player. You will need two solid slabs of suitable size (for example, two paving slabs), between which you need to place an inflated inner tube from a bicycle wheel. This makes a very effective insulating support for the turntable, although not very aesthetically pleasing. Very high quality and much more attractive stands are produced by, for example, Pro-Ject and Avid. Vibration-isolating supports can be considered as a more affordable, but almost equally effective alternative to a branded stand.

Specifications

- Power supply from an alternating current network with a frequency of 50 Hz and a voltage of 220 V±10%.

- Rotation speeds of gramophone records are 33 1/3 and 45 rpm.

- Rotation speed adjustment limits ±2…5%.

- The detonation coefficient is no worse than 0.15%.

- Reproducible frequency range 31.5…16000 Hz.

- Frequency response unevenness is no more than 10 dB.

- The pickup mismatch in frequency response is no more than 2 dB.

- The clamping force of the pickup is no more than 20 mN.

- The relative noise level with a weighting filter is no worse than -55 dB.

- Electrical background level -53 dB.

- Separation between stereo channels at frequencies:

- 315 Hz – no less than 15 dB

- 1,000 Hz – no less than 20 dB

- 5,000 Hz – no less than 15 dB

- 10,000 Hz – no less than 6 dB.

- Power consumption no more than 15 W.

- Overall dimensions 375x300x120 mm.

- Weight without packaging 5 kg.

Electrical circuit diagram of the EPU in the archive.

But a month ago I was given a “Sanyo TP6100” turntable, and I set out to use it, naturally after equipping it with a correction amplifier and proper modifications. So, naturally, initially an appropriate sparring was needed - a partner and the “Impulse” was brought to the Light of God. I didn’t specifically look for the reason for the different volumes of the channels, I don’t want to listen to this EPU, but “stretch my fingers.” I started with the power supply. Measurement of current consumption showed that under normal load the voltage drops to 9 volts, but should be 10 - 12 V.

It is clear that 12 V is better. At the same time, the step-down transformer got hot and the KT801B transistor got very hot. Which is natural, because the manufacturer himself wrote in the technical specifications about the permissible power of 15 W, and installed a transformer for 10 W. The KT801B transistor can have a static current transfer coefficient from 30 to 150, in fact it turned out to be 50, which is clearly not enough in this circuit design. I set the transformer to 15 W (as it was), I couldn’t find a better transistor - I installed a passive radiator on my original one, without checking the old ones, I installed other, proven electrolytes, instead of 2000 µF x 25 V - 4700 µF x 25 V, others at nominal. I loaded the updated power supply - now, even with a current output of 500 mA, the voltage did not drop below 10 V. And the real current requirement of the ECU is as follows: control board - 40 mA, electric motor - 150 mA, correction amplifier - 80 mA. Total 270 mA, I allow a maximum of 300. The transformer no longer heats up, but the transistor continues, although to a lesser extent.

The correction amplifier is enclosed in a shielding metal housing. For a class 2 EPU, this, as well as many other things, is already chic. Not only electrolytic, but also ceramic “flag” capacitors were replaced. Sockets are installed for the K553UD1A microcircuits. It will be interesting to listen and perhaps detect a difference in sound when changing them. There are about a dozen pieces in stock.

In addition to replacing the electrolytes and “flags,” the variable resistor on the control board was repaired. Instead of the indicated nominal value of 33 kOhm, it actually turned out to be 24 kOhm (that’s why adjusting the rotation speed was difficult). I opened the lid and used a file to reduce the width of the resistive layer, as a result of which the resistance increased to the required value, while I note that in the process of adjusting the disk rotation speed, it was discovered that a resistor with a higher resistance, for example 47 kOhm, would be appropriate here.

The EPU was assembled and turned on - it played, but one channel was still quieter than the other. Then I went into the tonearm and there, finally, the “weak link” was discovered - single pin connections, which were bad even for class 2. Having replaced the GZM-105 pickup with a GZM-005, I simply took and soldered these connections, the latter probably should be done this way, back at the factory. The sound of both channels became not only equally strong, but also subjectively of better quality.

For possible experiments, I placed the “output” in the corner in front of the correction amplifier. Now it is possible to remove the sound signal directly from the sound head, for example, try some other corrector. Also give a sound signal from another turntable - compare the operation of the correction amplifiers. So, having connected a “Sanyo TP6100” turntable to this corrector, which does not have a correction amplifier in its housing, I discovered that it does not function, or rather does not reproduce sound. Having built something resembling a microscope, I discovered the absence of a diamond needle tip in the stylus of the cartridge; there was only one pin in place, on which a diamond should be located and which was initially mistaken for it. For visual viewing, at least 10x magnification is required.

Upon completion of all actions, I have this internal view of the EPU. I was also not too lazy to make an additional headphone output on the front panel of the case - a huge convenience. Having read about the dependence of sound even on the brand of electrolytic capacitors, I incomprehensibly caught a less pleasant sound after replacing the electrolytes in the power supply unit that provides bipolar voltage for the amplifier-corrector and replaced them with the same ones, which turned out to be serviceable in all respects.

Finally, according to the recommendations of advanced music lovers, I installed the turntable strictly horizontally. There are several licensed records available, for this EPU it’s not even bad, releases from past years, somehow I’ll definitely step away from the everyday bustle and plunge headlong into the world of analog sound.

Is everything smooth?

A vinyl record is a rather unusual musical medium by today's standards. In particular, for best sound, its surface must be positioned absolutely horizontally. It is absolutely, and not relative to the floor, for example, which in our houses almost always has some slope. For this reason, a player installed on a table, despite all its external stability, will actually have a slight tilt (a couple of degrees) in one direction or another. This will have a negative impact on the sound quality and therefore the player needs to be leveled. In the best option, first level the table or stand on which the turntable is installed, and then the player itself. To control the horizontal surface of the disk and support, you must use a liquid or electronic level - the more accurate its readings, the better.

Everything is up for weighing!

One of the most important settings for a turntable is to correctly set the cartridge downforce, and since turntables are usually shipped with the counterweight weight disconnected, you will have to do this yourself. Typically, the pressing force of the pickup stylus to the record track is about 2 grams - a very small value, which must be set as accurately and carefully as possible.

You can check the downforce setting using special scales. This device has a platform onto which the needle is lowered, after which the set clamping force can be seen. Scales are not very expensive, but they will help maximize the life of the stylus and records. It may be noted that usually minimum and maximum clamping force values are given for pickups - you can set it according to the average value, or you can experiment, at your own peril and risk, of course.

Housing supports and base suspension

Their task is to isolate the base of the player from low-frequency vibrations coming from outside. Springs work well, especially in combination with rubber bushings - they are placed either between the base and the outer casing, or, less commonly, between the supporting surface and the supporting body of the player. In the second position, the magnetic suspension works best. For effective decoupling, it is necessary that the housing (or base) with the disk have a significant mass. The influence of these elements on the sound has not been confirmed.

Assembly

Turntables come in such a variety of designs and configurations that it is not possible to give one general advice on the initial assembly of a newly purchased turntable. Therefore, we will limit ourselves to a strong recommendation - carefully read the instructions supplied with the player, where the entire procedure is described in detail. We agree that in this age of Plug-and-Play devices, the instruction manual may look like something outdated and unnecessary, but we assure you that this is not the case with a vinyl player. Incorrect assembly or operation may damage your precious purchase, or, at best, prevent you from fully enjoying its sound. Some of the more advanced manufacturing companies post videos on YouTube that show the entire process of assembling and configuring their turntables, and these are also definitely worth watching.

Although most turntables come already equipped with everything needed for assembly, it's worth making sure you have the necessary tools to complete this process before you begin. Another important tip is to take your time. Allow enough time for assembly so that it can be completed thoroughly and calmly. Haste is not the best companion when working with a mechanical device, many of whose structural components can be easily damaged if handled carelessly.

But the player is finally assembled, and it’s time to start setting it up.

Results

Yes, perhaps after reading the article you got the impression that vinyl is very expensive and difficult. In part this is true. Considering that this article only considered a turntable, but in fact for a full-fledged audio system you also need to have a phono stage, an amplifier, speakers, and cables... All this costs a pretty penny and requires certain knowledge. If you have a desire to dive into this topic and study, then all this will not be difficult. If you just want to buy a ready-made combine (with built-in speakers, amplifier and phono stage), then you can go to the same “Republic” and buy a Chinese player, but you need to understand that the sound of such players is very far from classic vinyl.

I will talk about other necessary components in the next article. See you again!

- Tags

- instructions

- advice