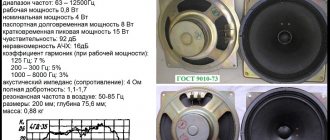

2-way speakers (pair 10GD-30 + 10GD-36)

I decided to create this project after digging through the website ldsound.ru and the ldsound.club on speakers 10GD-30 and 10GD-36 + “Serge” from Odessa impressed me with his speakers :-))

Goal and objectives of the project:

- creation of floor-standing acoustics for working with low volume levels;

- use of common LF and SB speakers of the USSR;

- simplicity of design and configuration of speakers;

- budget up to 100 green American rubles.

It was mid-July, it was hot, I sent my men to the seas and started work. I brought a cut of a 16 mm thick chipboard sheet:

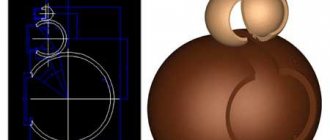

Body drawing:

In terms of displacement, the body is divided into 2 closed boxes - 60 liters for a pair of 10GD-30 , the rest of the volume is for ShP 10GD-36k and filters. The front panel is partially reinforced with 16 mm thick chipboard. The cost of cutting included a selection of 6 mounting holes Ø180 mm, but something went wrong at the “company” and I had to finish it at home, in the “rasp” mode.

Chipboard used the lowest grade - it is simply excellent in processing, but it crumbles easily and strongly absorbs moisture. But there is less carcinogenic impregnation, which is also good and compensates for all the shortcomings of Collecting. I glued and sealed the joints with Moment (50 kg gap).

To fasten the speakers I used furniture nuts, mortise, M5x8x17 and countersunk screws, white zinc, M5x35. After hammering in the nuts, I fixed them in place with the same “Moment” glue. The holes for the terminals were easily made by a “baller”.

I opened the inner surface with acrylic varnish in one layer and shot the 3 mm thick felt with a stapler:

I puttied the cases with finishing wood putty:

And at the beginning of August we went for sanding, painting and varnishing. The bottom and back wall were covered with matte black paint, and the main color was finished with “dark walnut” glaze, in 3 layers, coated with semi-matte varnish in 4 layers. In the role of hull supports from Amfitonov 35AS-018 :

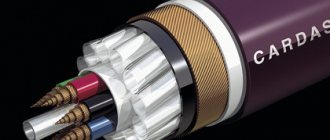

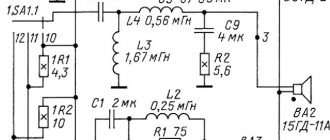

I figured out the filter layout:

Scheme:

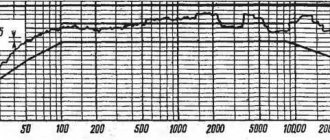

The frequency response of a broadband speaker is adjusted by ear using the R1\L2 chain - thanks to A.S. Bokarev . The corrected step is clearly perceived by ear and there are no problems in determining it!

The filters are ready, rebuilt and installed in the ShP box:

A representative of the Quality Control Department came :-))

The final touch is the grills. I cut 20x20 mm bars. I glued it together with the same “Moment” and shot the corners with a stapler.

I covered it with canvas, fixed it with a stapler, and then coated the corners with the wrapped fabric with BF type glue. The fabric for embroidery with threads is acoustically transparent, but has almost no stretch, so before fastening it is necessary to sprinkle it with water and stretch it “wet”. The width of the fabric is 1500 mm - one linear meter was enough, there was still some left over. The grills are attached with Velcro in 4 places. I cut out the legs from rubber gaskets for railway sleepers, 5 mm thick (8 triangular supports for the corners of the columns from 2 gaskets, glued them at the same time and nailed them with 20 mm nails).

I think it worked out quite well for the first time:

A few more photos to compare sizes. Amphiton 35AS-018 stands on a stand 300 mm high:

Impressions: I listened to a CD with different genres of music (like a sampler I made for myself), ULF Grundig V2000.

Pros . The result is quite good-sounding acoustics with a sensitivity of 90 dB, due to the use of a ShP speaker in the mid/high range, the sound stage is very clear. You feel like you're wearing huge headphones. When you first turned it on, it stuck for about 40 minutes). Well, the bass sound was much more pleasant than the Amphitons with FI. And most importantly, a two-strip of this type has a right to life!

Minuses. The sharp directionality of the squelch speaker, the body form factor that is unusual for me (I’m used to “wide-faced” boxes), and the weight turned out to be 27 kg each - no joke

Conclusion. A very simple, “sounding” speaker is made from practically nothing and can be replicated “on the knee” for a very low budget!

PS I will immediately answer questions about the frequency response and microphone measurements - low-frequency cutoff 500 Hz - (see frequency response 10GD-30 ) and midrange/high frequency. An operating frequency of up to 20,000 Hz with a correction circuit (see frequency response 10GD-36K ) provides a completely linear frequency response of the speaker, without measurements. I called a friend, he wanted to listen to the newly purchased “young vintage” Yamaha RX-530 receiver. An hour after listening, he paid for the project and left for the new owner’s house. :-))

Now I’m thinking of repeating a similar project, but 3-strip (pair 10GD-30A,B + 4GD-8E + 6GD-13 ) in cases from 35AS-018 + cases 10AS-232 “Cleaver” . There will be a hybrid of 50AC-022 and 20AC-7 Corvette , fortunately the hull is still there.

Author: Yuri (5G98 “Accord”)