↑ Criticism of Soviet small-sized speakers

The first mass-produced small-sized but high-quality Soviet speakers were 10MAS.

Acoustics 10MAS-1 from Estonia-006-stereo The main distinguishing features were relatively modest size with increased bass response, as well as only two speakers (to save size).

Further - more, the size of the speakers became smaller, the sound - worse. Users were happy that they could be put into a niche in a furniture wall, placed on a cabinet under the ceiling or on the floor. This completely killed the sound, but few people cared, and the rattling of dishes in the cabinet with the speaker aroused delight and pride.

What are the shortcomings of a family of such models, of which dozens were produced? In my opinion, the root of all evil is dual-band and incorrect frequency division. I believe that speakers such as 10GD-30, 25GD-26, 6GD-6, 10GD-34, 15GD-14 and the like are fundamentally unable to sound well down to 5 kHz, which is the usual crossover frequency in two-way speakers with these speakers . By the way, you won’t hear a good word about the partners of these speakers - 3GD-31, 10GD-35 and the like, without design modifications and complex filters, they do not work the best.

It must be said that there were decent two-way speakers that could sound good up to 5 kHz, but they did not require small-sized enclosures, so they were not used.

Progress moved further along the road to absurdity

, The speakers became smaller and smaller, and so did the speakers for them. Systems 15AC and 25AC were produced in large quantities, and there are still many of them on the secondary market at reasonable prices. It would be tempting to improve them with minimal rework and expense.

↑ Acoustic systems 15AC-109

I think these columns are worthy of improvement. If their body is not damaged, then it looks good, the volume is satisfactorily sufficient for a standard speaker, there is FI.

Photo source: vega-brz.ru

The 15AS-109 is equipped with 15GD-14 (25GDN-3-4) and 10GDV-2-16. The section is at a frequency of 5 kHz and cannot be changed because operation of the 10GDV-2-16 below is impossible. Therefore, the sound is sluggish, gray, dull due to the indistinct reproduction of mid-frequencies (the most important for the overall perception of sound) frequencies. And this applies not only to this model, but also to all two-way speakers in which the previously mentioned woofers are installed.

The best Soviet designers knew this very well and, to modernize such two-way radios, they suggested that radio amateurs install full-fledged midrange speakers, such as 2GD-40. Alas, the insanity of miniaturization did not allow anything additional to be placed in tiny cases, especially in a box, because the volume was already insufficient.

External birdhouse towns were proposed, which sounded good, but achieving a cultural appearance was difficult. In addition, no matter what they say, the 2GD-40 and the like worked according to the data sheet up to 12.5 kHz, above that there is a break, and the directivity above is needle-shaped, i.e. you need a three-strip in a new housing and with new filters, from the old speakers there was only one woofer left. The option is good and I made such a three-strip, basically only on available Soviet speakers, but that’s not what we’re talking about today.

15AC-109, 15AC-110

Acoustics with many names. It was made by PO Vega, Berdsk.

25-ac-101 VEGA 15AC-109, 15AC-110 - produced since 1980. Since 1989, they began to be called “25AS-101″ and “25AS-102” according to GOST 23262-88. The difference between 15AC-109 and 15AC-110 (25AC-101 from 25AC-102, respectively) is in the nominal resistance - 4 and 8 Ohms, respectively. The recommended power of a high-quality household amplifier is 20…25W.

| Specifications | |

| Reproducible frequency range, Hz | 40…20 000 |

| Uneven frequency response, dB, at the lower limit frequency of the reproduced frequency range relative to the average sound pressure level | – 8 |

| Frequency response unevenness, dB, in the frequency range 100…8000 Hz relative to the average sound pressure level | ±4 |

| Average sound pressure at rated electrical power in the frequency range 100…8000 Hz, Pa | 1,2 |

| Level of characteristic sensitivity, dB (Pa/√W) | 84 (0,317) |

| Heads: 25 GDN-3-4 , 10 GDV-2 | |

| Harmonic distortion % 250…1000 1000…2000 2000…6300 | 2,0 1,5 1,0 |

| Nominal resistance, Ohm | 4 / 8 |

| Minimum value of total electrical resistance, Ohm | 3,2 / 6,4 |

| Rated power, W | 15 |

| Maximum noise (nameplate) power, W | 25 |

| Maximum short-term power, W | 50 |

| Type of low-frequency acoustic design | bass reflex |

| Bass reflex tuning frequency, Hz | 45 |

| Crossover frequency, Hz | 5000 |

| Weight, kg | 6,8 |

| Dimensions, mm | 360x220x190 |

Features: The body is made in the form of a rectangular non-collapsible box, veneered with valuable wood. The front panel is covered with a decorative plastic overlay, which simultaneously serves as a decorative frame for the bass and treble heads. The body is made of 12 mm thick plywood. Speaker height – 360 mm, width – 220 mm, depth 165 mm (190 with front grille). The body is not collapsible. There are 3 holes on the front panel: rectangular for a bass reflex 35x80 mm; round hole with a diameter of 90 mm for a high-frequency speaker; another round one for the bass/midrange speaker with a diameter of 115 mm. The front and back walls are slightly recessed inward by 1.5-2 mm. The seats for the speakers and FI are recessed - milled to a depth of about 5 mm. The front panel is plastic, has 3 holes for speakers (covered with a metal mesh) and one for a bass reflex with a decorative “divider”. It is attached to the speaker body using 6 screws, the heads of which are covered with decorative caps. There are foam rubber pads at the points of contact with the speakers and FI. The speakers used heads: 25 GDN-3-4 , 10 GDV-2 (heads are produced by Vega Production Association, Berdsk). The heads are installed on the front panel along the central vertical axis of symmetry. All heads are covered with protective nets. A decorative nameplate with the name is attached to the upper part of the front panel; under the nameplate there is a hole - the bass reflex output, covered with a decorative grille. Bass reflex dimensions: diameter 42 mm, length -190 mm. Tuning frequency 45Hz. The terminals for connecting the connecting cord are located on the rear wall of the housing. The internal volume of the speaker is 8.5 dm3. Inside the speaker housing, electrical filters are mounted on the board, providing electrical separation of the speaker bands. Separation frequencies are provided by filters on the LF side of the 2nd order and on the HF side of the 3rd order. Crossover frequency 5000Hz. 1 – plywood body, 2 – FI, 3 – HF head 10GDV-2-16, 4 – LF head 25GDN-3-4; 5 – filter board, 6 – foam damping, 7 hole for cable

↑ Refinement of speakers 25GDN-3-4

The 15AS-109 has 25GDN-3-4 speakers installed, these are good speakers, brothers of the 10GD-34, but much better than them due to the huge powerful magnet.

As a result, they can operate normally at a volume of 8...12 liters, provide output from 30...40 Hz with a decay of not 15 dB, like the S-90 and the like, but 3...6 dB. Of course, the volume of moving air and power are not comparable to the 75GDN. A common problem with most Soviet speakers with a rubber surround is its hardening, which causes an increase in the resonant frequency and quality factor, and this leads to a deterioration in quality. If initially (during manufacture) the suspensions were normal, you can try to revive them. If tight hangers have already been installed at the factory, only replacing them will help.

What can I advise from practice? Take cotton wool, good gasoline (“Galosh” or similar), cut a circle out of cardboard the size of the paper part of the diffuser and attach it so that less liquid gets on the paper. Next, moisten the cotton wool and generously moisten the rubber suspension from the front part.

Yes, gasoline evaporates quickly, but dry rubber greedily absorbs gasoline, changes before your eyes, and turns from dull to shiny. Of course, all work, especially with flammable liquids, requires appropriate safety measures.

So, we wet the rubber from the front until it refuses to drink gasoline. Then we place the speaker with the magnet facing up and pour gasoline into the groove of the corrugation, wait until it is absorbed and evaporates. Immediately after complete evaporation, it is useful to warm up the dynamics for an hour or two with low frequencies at the resonant frequency (easily determined by eye), achieving maximum amplitude, but without knocking the sleeve on the magnetic system.

If the tires were really dry, they will change and the speaker parameters will noticeably improve. Of course, it is best to take measurements if possible. In my practice, there were both cases of a decrease in resonance by 20 Hz, and a minor effect of just a few Hertz.

The problem is that after a couple of days a partial rollback of the improved parameters occurs. To consolidate your achievements, you need to use a car drive belt restorer. It is sold in aerosol cans. I think they are all about the same, I bought "Belt Dressing & Conditioner" from Permatex.

We cover the corrugation with foam on both sides alternately 2-3 times (this is where you will need a cardboard circle, without it there will be spots and unsightly streaks on the diffuser) waiting for it to dry each time.

The effect of this treatment is long-lasting, clearly present for more than six months (in my experience). The rubber becomes completely different to the touch - soft and slightly sticky, and shiny to the eye. Warming up with maximum amplitude is also advisable. The resonance decreased from 60...65 to 45...50 Hz, i.e. it became like the new speakers.

Reader vote

The article was approved by 124 readers.

To participate in the voting, register and log in to the site with your username and password.

Hello friends.

Despite such a venerable age for the speakers, they are preserved in excellent condition - as if they were bought just yesterday at the Melodiya store. Polished without scratches or abrasions. The plastic is also intact and smooth. All this can be seen in the photo - click on the image to enlarge.

The marking was still old GOST, not 15AC - 404, but simply 15AC-4

I was also pleased with the filling. The screws had factory seals and all internal components have survived untouched to this day.

The speakers and filters seemed to say with their appearance - “Yeah... it’s hard to find people like us now!”

It's always a pleasure to remodel an acoustic in such excellent condition. I want the sound to match the condition. And I got to work.

I didn’t want to do anything supernatural, as we know, the best is the enemy of the good. The goal was to get rid of all the weak points and see what would come of it in the end.

The weak points in such household Soviet acoustics are as follows:

- insufficient volume of housings

- no filter on the woofer

- poor sealing

- appearance (not for everyone, but these ones clearly require improvement)

So I decided to eliminate them as much as possible and give these speakers a second life

The first thing I did was install the speakers on the outside of the case and seal the inside with a layer of technical wool (cotton).

For these purposes I used PVA glue. The cotton wool that comes with the acoustics - the original “mats” that were in the speakers delaminate perfectly and you can separate pieces of the required thickness. I made it about a centimeter thick.

So with the volumes, I did everything I could in the format of the body data.

It's time to get started with acoustic filters.

These speakers have a filter installed only on the high-frequency section.

Its function is performed by the 3GD-31 speaker (more modern marking 5GDV-1-8). It was used in many other acoustic systems, the most famous of them is perhaps the COMET 25AC-225 (aka 15AC-225). Some people criticize this speaker, others praise it. Everyone's taste in markers is different.

I like it, and when I was assembling a floor-standing three-way acoustic system (I’ll write about it in detail another time), these speakers took pride of place in the high-frequency section.

They had a second-order high-pass filter in the form of a capacitor and a coil.

There is no low-frequency filter at all. The speakers 25GD-26-30 (grandfather of the speaker 35GDN-1-4), which serve as low-frequency speakers here, are connected directly.

By the way, the VEGA 10MAS-1M speakers are very similar to this acoustic system. Actually, 10MAS-1M is a steroid clone of our 15AS-404 - the only difference is in the size of the case, in 10MAS they are one and a half times larger and in resistance - 8 Ohm 10GD-30 are installed in 10MAS.

By the way, on the basis of these cases, I built myself wonderful shelf holders, I’ll also write about them someday, I have the material - the photos are stored somewhere in the bins of the hard drive.

Here's what I did with the filters: I removed the coil from the second-order high-pass filter and added a modern capacitor to it to get a second-order low-pass filter.

The remains of the high-frequency filter in the form of a resistor and capacitor were also replaced by a modern Conder, thereby making a first-order high-frequency filter - it will be enough to prevent low frequencies from reaching a cannon shot.

It was simply necessary to cut off high frequencies at the low end so as not to interfere with high-frequency vibrations in reproducing the velvety and rich bass that the 25GD-26-30 speaker is capable of.

Now that I’ve dealt with the second ailment, now it’s time to work on the tightness.

The internal seams in this acoustic are coated with some kind of Soviet wood glue.

I don’t know what kind of glue this is, but it has been preserved perfectly. My attempts to pick out a piece were unsuccessful - it is hard and durable as a stone. So let it stay. But the foam rubber gasket that seals the back cover has turned into a jelly-like dark red substance over time - it needs to be replaced.

If you have ever disassembled Soviet acoustics, especially Radiotekhniki speakers (S30, S50, S70 or S90), you have seen that sealing was often carried out with Velcro (like the one that was placed in the interpanel seams of Soviet Khrushchev-era buildings) or plasticine.

In this matter, I did not stray far from the origins, since the method is very practical. After all, if you sit, for example, on a sealant, then if necessary, open it and repair it - you will spend a lot of effort.

Unfortunately, I didn’t have any supplies of Velcro from school, and I didn’t want to use regular plasticine - it could leave behind greasy stains. Therefore, I chose the best option - window putty. It is very plastic - like plasticine, only it softens in your hands much faster and does not leave greasy marks. This is what I used when sealing the cases.

The last item left on the menu is appearance.

The speaker frames and front panel were painted with matte spray paint and began to look very massive and nice. But this approach to painting speakers is categorically unacceptable - spray paint will greatly affect their sound quality, not for the better. The Internet offers various options for how to paint the speaker diffusers themselves, but each has its own disadvantages:

- special paint for speakers - very expensive

- grated pencil lead - it smudges and crumbles over time

- with a black marker core - not for everyone, the color will have a brownish tint

- ink from an inkjet printer - does not paint over areas covered with glue

I also wondered what to paint the speakers with.

And through some logical thinking, I made an assumption about the ideal paint option and was right. I am happy to share it with you: the paint is water-based, safe for impregnating speakers, paints over all areas with glue, and after drying gives a noble matte color. After drying, the color perfectly matches the original color of the pendants. This is stamp ink! The same one that is poured into print pads. In case there are many different colors, I’m posting a photo of the one I use. Painted with a cotton swab in one layer.

Well, that's almost all. The final touch remains - replacing the ancient wires with normal terminals. Well, there’s no problem with that - you can buy anything to suit your taste in every radio store, I chose these:

↑ Replacing speakers 10GDV2-16

The 10GDV2-16 speaker fundamentally cannot operate from 2...3 kHz, so it can only be replaced. The main requirement is a low resonant frequency of 1...2 kHz without overshoot at resonance. I think 2GD-36 and 4GD-56 will do, but they are inconvenient to install, so I didn’t use them. I installed Philips AD0142 with a resonance of 1300 Hz, the result was not bad.

This is an intermediate option before setting up FI.

I understand that few people have these Philips, and I didn’t want to put them here because there are good complete Philips subwoofers for them. But the conclusion is this:

you can use a wide variety of tweeters with a low resonant frequency and good sound, including paper ones. Due to the low output of the woofer, the sensitivity of the tweeter will always be higher. But in this case, you will have to do the band mixing yourself, and I can only share filters for the speakers I worked with.

↑ Chinese tweeters Alphard TW-302

For this budget project, I didn’t want to use tweeters whose cost per unit was higher than a pair of speakers, and the size also played an important role. That's why I bought these cheap (but not the cheapest) tweeters.

It was interesting to listen to these “silk” domes.

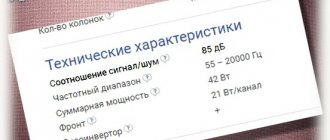

The “silk” here is clearly synthetic, the reinforcement threads are sparse, but the material is very soft and elastic, sharply different from plastic membranes. The case is plastic, but it’s bad - it gets scratched, there’s no rigidity. The declared parameters of 8 Ohms and 95 dB turned out to be “Chinese” - the resistance is 4 Ohms (impedance over the entire frequency band, not just measured by a tester), and the sensitivity... I can’t measure it accurately, and there’s no need to, according to my estimates, 88 dB. Is there a difference with 95 dB?.. However, the resonance is 900 Hz and 1200 Hz, the sound is not bad, the membranes can be easily replaced. In general, “third grade is not a waste.”

"15 AS-109 Vega" vs "S-30 Radiotehnika"

Since the site has already collected an almost complete collection of acoustics and speakers from the USSR, I will try to make comparisons between two similar models. In it I will not write in the direction of my choice or sympathies, but will only present visible facts.

I'll start with 15 AC-109 Vega and S-30 Radiotehnika - these are bookshelf 2-way speakers with a bass reflex. They are quite popular and familiar to many. Externally, they differ radically, but the location of the speakers in both speakers is in the center, along the vertical axis, only in the “Vega” the output of the bass reflex pipe is located above the tweeter, while in the “S-30” it is on the side, under the woofer.

Specifications (from the book):

| Options | 15 AS-109 | S-30 |

| Frequency range | 50-20000 | 50-18000 |

| Frequency response unevenness | ±4 dB | ±6 dB |

| Resistance | 4 ohm | 4 ohm |

| Nameplate power | 25 W | 30 W |

| Crossover Frequency | 5000 Hz | 5000 Hz |

| SOI | 2% | 2% |

| Dimensions (HxWxD) | 360x220x190 | 364x214x195 |

| Weight | 6.6 kg | 6 kg |

Appearance

One can argue here endlessly, but I believe that each speaker has its own appeal, which has long become a classic. The front panel of both is covered with a decorative plastic cover. The speakers are protected by metal mesh. “Vega” has one minus: the hole in the bass reflex pipe is slightly covered and this interferes with the passage of air at large amplitudes, which creates slight interference.

Frame

For “Vega” and “S-30” it is made of plywood and veneered on top. The thickness of the housing panels is about 12 mm. The internal volume is approximately the same as the external dimensions of the cases. The inside of the “Vega” has a back wall covered with 10 mm thick foam rubber; the “S-30” has cotton wool inside.

Woofers

Vega has more powerful speakers 25 GDN-3-4 , this allows you to receive more power and lower frequencies in comparison with “S-30” ( 25 GDN-1-4 ). The Vega’s ferrite ring has an outer diameter almost as big as the basket itself. The rest of the material is identical.

Tweeters

Here, “Vega” also has more powerful speakers 10 GDV-2-16 , which were installed in top-end 3-way speakers. They have higher sensitivity and more power. The “S-30” has 6 GDV-1-16 , they are not so powerful, they have less sensitivity, but they were also installed in high-class speakers. The emitter area and material are the same.

Bass reflex

“Vega” has a slot port with an area of 13 cm2 and is tuned to 45 Hz, while “S-30” has a round port with an area of 7 cm2 and is tuned to 50 Hz. The pipe material of the Vega is made of plastic, while the S-30 is made of foam rubber, which begins to crumble over time. Due to its larger area, shape and material, “Vega” completely wins.

Electrical filters

All models are made of good elements, coils on air cores, non-polar capacitors, paper or film. But the “S-30” has an overload circuit added (its effect on sound quality is debatable) and the filter itself is made on a PCB board. The circuits are approximately similar, the orders are the same, but “Vega” does not have a damping resistor at HF. In the “S-30” the cut on the low-frequency dynamics is made “steeper” in terms of graph and more correct. The terminal block, in the “S-30” it is full-fledged with screw terminals, while in the “Vega” the output is made through a cord.

Sound

I had a chance to listen to both speakers. “Vega” will have a more interesting sound due to deeper low frequencies. But, if you listen not loudly, then “S-30” plays more pleasantly. In terms of maximum power, “Vega” will win, although the characteristics show the rated power in favor of the “S-30”.

This comparison does not pretend to be ideal and is a personal opinion. Below you can use the link to go to the forum and vote for the best speaker of your choice.

Forum with poll.

Author: LDS , for ldsound.ru, August 2019

↑ Refinement of hull 15AC-109

I will not go into detail, since it has been described many times, but I will focus on the most important.

This is a thorough sealing, filling all joints and cracks from the outside and inside. It is advisable to check using the LIMP program - the cracks are very clearly visible. It is advisable to remove epoxy drips on the front panel with a chisel and smooth out any unevenness.

Install a spacer inside tightly between the front and rear panels. I placed a block with a cross section of 20x40 mm. Place the spacer between the holes for the speakers.

For the Alphard TW-302 tweeters we had to make an additional panel with a hole for the magnetic system, it’s inside. Screws are screwed into this panel through the holes in the tweeter, and it attracts the head to the front panel.

Faux suede pads are cut out for the speakers. I recommend replacing the screws with more modern ones.

Fill the holes for the speaker wires with glue, install spring clamps on the back; unfortunately, normal terminals with screw clamps could not be installed due to lack of space.

If desired, the outside of the body can be varnished or otherwise refined. Inside the housing, be sure to fill it tightly with fluffy padding polyester, but leave a passage between the hole of the FI pipe and the woofer.

Instead of a nasty standard plastic panel, I made a frame from a thin laminate and stretched canvas-type fabric over it. Attaching the frame to the body via Velcro is simple and does not require drilling holes. Due to my inexperience, I installed too long pieces of Velcro and removing the frame turned out to be oh so difficult!

Modification of “Vega 15 AS-109”

My aunt had a vinyl record player - VEGA 109 STEREO, complete with speaker systems - 15AC-109. After moving to her, this farm fell to me. Six months of listening to these speakers gave me the idea to modify them a little - muffle the cabinet and level out the frequency response. And now I finally did it to the end!

I’ll say a few words about the possible replacement of speakers: in place of the 10GDV-2 you can install something like Peerless 830827, making the crossover frequency as low as possible. In this case, the turbidity of the 25GDN-3 at mid frequencies will be eliminated and the system will sound great! But ordinary high-frequency heads with a high resonant frequency will not fit here, otherwise you will have to change the woofer, and this is a story called “assemble the speakers from scratch.”

Refinement of the body

The first step is to disassemble the speakers - unsolder the speakers, speaker wire, pull out the filter and unscrew the bass reflex. In two-way systems, often the woofer operates both in its range and in the midrange, where it is picked up by the tweeter. But! The dimensions of the speaker cabinet affect the mid-frequency range. The wavelength coincides with one or even two dimensions of the housing - the result is a standing wave that distorts the frequency response of the system at medium frequencies. In our case it is 1000-2500Hz. Therefore, wave reflections must be suppressed as best as possible - then the frequency response of the system will be more even.

The 15AC-109 cases are not very large, so materials that disperse (I use egg trays) and suppress (foam rubber, felt, isover) sound waves cannot be put in there. Therefore, the only thing that can be done is to cover the body with either foam rubber or felt. Felt can be taken up to 10mm thick, while foam rubber can be up to 20mm thick, since it is less dense. You need to glue 10mm foam rubber or felt to the bottom of the speakers - there is very little space there (otherwise the woofer dynamics will be “stuffy” from below). In general, I prefer to cover speaker bodies with felt or isover - they are not subject to aging. For gluing, you can use either a canned “Moment” or a carpenter’s “Moment” - both dry quickly, although the second does not smell as strong as the first. And it’s even better to use automotive vibration-absorbing mastic for these purposes - it absorbs and sticks, but it smells... The main thing in this process is to coat all the joints of the body with an adhesive substance.

It is also necessary to strengthen the bass reflex pipe as best as possible - it is too flimsy and thin - it must be covered with felt (at least synthetic, as I did). Then cut out a sealing gasket from the same felt that will be located between the FI and the body, coat it on both sides with “moment” and screw on the bass reflex. The results of the work done can be seen here. We're done with the body, but how does the frequency response of the acoustics behave?

Description 15 AS-109 “Vega”

Refinement of the electrical part

I did not change the speakers, deciding that I could achieve good results with the old ones. All frequency response measurements were carried out using the LSPCad 5.25 application – JustMLS. In all cases, the distance from the microphone to the tweeter flange is 80cm. This distance was chosen based on preliminary measurements: distances of 50cm, 80cm, 1m were tried. In the end, I chose 80cm, since at 50cm the frequency response is a little “directional” (the deviation from the acoustic axis is large), at 1m the phase is measured incorrectly, although the signal at the speaker input is already large (in general, too loud). The microphone is located at the level of the acoustic center of the speakers (at a height of 95cm). Below are the frequency responses of the left and right (if you want, the first and second) speakers with original (factory) filters.

Frequency response 15AC-109 with original filter.

When I started everything, and it was a long time ago, I did not have calibrated microphones, a normal sound card, or the skills to build separation filters. So I experimented as best I could. Having “processed” the case, I started working on crossover filters - I tried (before the appearance of the “intuitively” calculated filter) to invert the phase of the high-frequency speaker - I liked the work of both speakers in phase and I left it like that until better (read, today) times. Now, having restored the design of the factory filter, I found out why I liked the in-phase performance of the speakers. As you can see below, the dip at 4 kHz has decreased, the hump at 11 kHz has become lower, as has the level of the HF components:

Frequency response 15AC-109 with a native filter and an inverted high-frequency speaker.

After some time, using simple formulas and using the JBL Speaker Shop program, I calculated a filter with a crossover frequency of 5 kHz. I took the measured speaker impedance, rated sensitivity and frequency range as a basis. And a resistor connected in series with the high-frequency section, and the phasing of the speakers was selected by ear. That’s why I called the filter “intuitive”, since there was no real frequency response, phase response, or frequency response - there was nothing to simulate with, and I had not yet heard of the LSPCad package. Thus, the following diagram was obtained:

Schematic of an “intuitive” filter.

The measurements carried out now have shown good results (see below). Although the crossover was made without taking into account the dynamic drivers' own frequency response, its structure had a beneficial effect on the amplitude response, although only of one speaker (it all depends on the speakers). But this characteristic does not clearly determine sound quality. Therefore, subjective listening was required (third parties were my brother and father), which revealed a preference for the new filter rather than the old one. The voices have become more intelligible, the muddiness of the sound has partially disappeared, and now you can hear the plucking of the strings, although there is some “glassiness” and harshness. Apparently this is due to the fact that the high-frequency head is given a larger operating range - it plays with 5 kHz, and not with 6 kHz as it was in the factory filter.

Frequency response of acoustics with an “intuitive” filter.

But this crossover still did not satisfy me, I knew that more could be achieved, especially since I now had the means to completely correctly measure frequency characteristics. To build a crossover filter from scratch, you need the axial frequency response of each speaker in the acoustic design and their frequency response. Armed with an LCR meter, I set up the necessary “boxes” and took measurements.

Let's look at the frequency response of dynamic heads separately. Below are graphs (frequency response and phase response) of two copies of high-frequency speakers, and below - two copies of low-frequency speakers for a visual comparison of the “repeatability” of domestic sound emission samples:

Frequency response of high-frequency speakers.

Frequency response of low-frequency speakers.

As a result of modeling (the LSPCad 5.25 package was used), I came to a circuit containing a first-order low-pass filter and a third-order high-pass filter. A Zobel circuit is used to equalize the impedance of the low-frequency head. In the high-frequency section, a divider-transformer of the input load resistance (HF HD coil) is used. Thus, over the entire frequency range, the impedance of the speaker system has slight deviations from the nominal value (4 Ohms).

Diagram of the new filter.

Frequency response of acoustic systems with a new filter.

Impedance of speaker systems with a new filter.

The measurements were taken from a fairly large distance in a living room. The goal was to measure the range adjacent to the crossover frequency, not the entire frequency range. In this case, it didn’t matter to me that it was below 2000Hz - and there was the influence of the room.

About the directionality of acoustic systems

As can be seen below, off-axis measurements were taken at 15 and 30 degrees with 1/6 octave smoothing.

Comparison of the axial frequency response of the left speaker with off-axis ones

Comparison of the on-axis frequency response of the right speaker with off-axis ones

With an increase in the angle of deviation from the acoustic axis, the characteristic does not tend to “go” down, which means that the directivity of the high-frequency driver is quite weak. The dip at 12.9 kHz turns into a hump at 13.7 kHz - apparently this is the resonance of the acoustic lens of the tweeter. With a deviation of 15 degrees, the frequency response becomes smoother (almost ideal), as interference phenomena are reduced. Thanks to the bevels on the front panel, diffraction on the axial response is almost invisible. In the band separation zone, only at a 30-degree deviation there is a slight drop (2dB) in the frequency response of the woofer, which does not significantly affect the overall course of the characteristics.

What's with the sound?

The sound is better than it was with my old filter, and even more so with my native one. The dip around 4 kHz disappeared, so the vocals became lively, unveiled, the guitar became a guitar, not a dombra. But, as already mentioned, there is some rigidity and glassiness. And due to the fact that the 25GDN-3 plays in the mid-frequency band, on vocals and violins its sound becomes muddy, compensated by the sharpness of the high-frequency head. Overall, I'm pleased with the sound.

Author of the work: Efremov Alexey

↑ Correct AC filters

We often see how home-made people think that filters are something of a tertiary importance; by audiophile standards, it is enough to install one capacitor and one coil at most.

In my deep conviction, everything is quite the opposite - filters are the most important element of speakers, the wrong filters can ruin the sound of any speakers. First-order filters can work with well-matched pairs of speakers that have a natural roll-off at crossover frequencies without humps or spikes. In the vast majority of cases, it is difficult for us to find such pairs.

And I am also convinced that it is impossible to quickly and correctly debug filters without acoustic measurements. The benefits of any calculators are amazing, since they use resistors as models, although speakers are complex electromechanical systems with resonances and other features.

The exception is LSP CAD and only if you feed it the results of microphone measurements.

It was possible to achieve a very simple filter circuit, with a minimum of standard ratings (there was special emphasis on this).

Capacitors K73-16, all parts are placed on the plywood of the old filter for convenience. The installation was done using an acoustic cable with a cross-section of 1.5 square.

This is what happened in LSP CAD

And here is the result of measurements with a microphone. Compare.

Here's the impedance graph, it doesn't drop below 4 ohms anywhere, so the speakers will work fine with any 4 ohm amplifier.

And here’s what LIMP showed in the box, where there seemed to be no obvious cracks...

Below 300 Hz in a normal room, due to reflections, measurements are difficult to make, so they are taken point-blank.

Point-blank measurement of the modified 25GDN-3-4 speaker, the FI port is plugged. It can be seen that at a level of -3 dB the lower frequency is 45 Hz. Find the frequency of -15 dB, as is usually measured for industrial speakers, using the graph yourself. After turning on and adjusting the FI, we managed to lower the frequency, but it is difficult to plot the measurements due to the distance of the FI hole from the speaker.

I repeat, despite the low reproduced frequency, you should not expect the same bass as from the S-90 due to the tiny size of the diffuser, but this is enough for tonal balance. From my point of view, tonal balance is extremely important.

↑ Listening to the updated 15AC-109

The speakers were made back in the summer.

Of course, they do not pretend to be “hiendas”. We compared it with my homemade three-way three-body version on the 25GDN-3-4 with fashionable sequential filters, and with the Tandberg 2510 (does anyone remember this company today - Hi-End of the 70s?). Naturally, they are inferior to both. However, after the rework the speakers clearly became better

. I am sure that they are better than any factory 15AC, S-20, S-30, all sorts of cubes, etc. The sound is clear, clean, compared to the three-way version there is a slight coloration, which is not surprising since the tweeter operates from about 2 .5 kHz, and below is a subwoofer.

A prerequisite is to work on a stand, at least on a stool. If the bass is recorded on the disc, it is also in the speaker; if there is no bass in the recording, then the speakers do not reproduce it. For normal volume levels in the room, up to 4 W per channel is sufficient. “Sibilants do not irritate.”

In general, the speakers play quite brightly, but not intrusively. The tonal balance is shifted slightly upward compared to the above speakers.

Their small size allows them to be placed even on a computer desk. The speakers are quite heavy, which is rather an advantage.