As a child, one of my friends had Vega 50AC-106 speakers at home, then they sank into my soul with their design, of course, because then, in the early 90s, for me, boys, these speakers with their plastic linings were something cosmic, top perfection. Well, we didn’t think much about the quality of music then. I would like to have these for myself. Time has passed, but those speakers remain in my memory, as does the desire to receive them. Opportunities for their acquisition also appeared.

The photo is not mine, taken here

A small digression. This post does not pretend to be the ultimate truth, nor does it pretend to be any audiophile delights, nor does it claim that the result obtained breaks all records. Please don’t argue about “why are you bothering with them, it would be better to buy new normal ones”, I wanted exactly THOSE speakers, as a memory from childhood. To listen to music, I have Hifiman HE-400i headphones and a homemade tube amplifier for them; this set already claims to have some quality, although I’m not going to argue with audiophiles.

Anyone who is interested, I ask under cat.

Speaker system design

The Vega column includes several elements

- Frame

- High Frequency Speaker (HF)

- Midrange speaker (MF)

- Subwoofer (LF)

- Frequency filter

The audio frequency signal comes from the amplifier to the speaker filter, where it is divided into several components (HF, MF and LF), then each frequency is fed to its own speaker.

To prevent parasitic distortions, the inside of the speaker body is lined with cotton wool, and in the places where the front and rear panels are attached - with foam rubber.

Restoration and modernization of speakers 50 AS-106 “Vega”

As a child, one of my friends had “Vega 50 AS-106” speakers at home, then they sunk into the soul with their design, of course, because then, in the early 90s, for me boys these speakers with their plastic linings were something cosmic, the height of perfection. Well, we didn’t think much about the quality of music then. I would like to have these for myself. Time has passed, but those speakers remain in my memory, as does the desire to receive them. Opportunities for their acquisition also appeared.

A small retreat

This post does not pretend to be the ultimate truth, nor does it pretend to be any audiophile delights, nor does it claim that the result obtained breaks all records. Please don’t argue about “why are you bothering with them, it would be better to buy new normal ones”, I wanted exactly THOSE speakers, as a memory from childhood. To listen to music, I have Hifiman HE-400i headphones and a homemade tube amplifier for them; this set already claims to have some quality, although I’m not going to argue with audiophiles.

Purchase and initial inspection

Everything turned out very simple with the purchase, I found that same friend from childhood and it turned out that he still had those same speakers. Although they are in the closet and have not been used for ten years. For a symbolic sum, we shook hands and the speakers went to me.

Immediately upon purchase, I was told that one tweeter had burned out and required replacement. Plus the speakers were pretty dusty, and there was rust on the metal grilles. Next, the speakers were connected to an amplifier to check their functionality. All speakers turned out to be working except one HF, which was confirmed by its continuity tester later.

Of course, the sound of the speakers as is did not please me. After the first turn on, the speakers were completely disassembled. The case has been checked for the strength of the seams; often, with old Soviet speakers, the side panels simply come apart. I was lucky, all the joints were glued tightly; by the way, my cases were made entirely of plywood, including the back wall, which is not often found in this model. Much more often the side walls are made of plywood, and the back is made of chipboard.

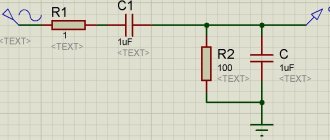

Next, the filter was completely disassembled to check its compliance with the original circuit, by the way, here it is:

The capacitors and resistors matched the values of the circuit. All my capacitors were metal-paper MBGO, which in general is not so bad, because in real designs people have also encountered electrolytes. By the way, after measurement, the capacitors showed deviations from the nominal value within 1%, which is simply wonderful.

But most of all I was interested in the inductance of the coils, but with them, as expected, I had no luck. None of the coils matched the circuit in terms of inductance, and moreover, the coils also did not match each other in pairs of columns. For example, the inductances of the LF coils were 0.85 mH and 0.64 mH, although according to the circuit it should be 2.8 mH. With midrange and high frequency the story is exactly the same. Well, oh well, the scheme will still be completely redone.

After the initial inspection, a rough plan was drawn up:

- Sealing all seams, joints and holes from the inside of the speakers with sealant;

- Gluing wooden spacers inside the body according to the front-back and left-right pattern;

- Treatment of all walls with rubber-bitumen mastic to reduce resonances;

- Pasting all walls with a layer of batting;

- Replacement of high-frequency speakers with the production of new podiums for them;

- Complete rework of filters with changes in circuit design and part ratings;

- Replacement of all seals under the speakers;

- Replacement of all wires;

- Installation of ports with terminals;

- Washing panels and painting grilles;

- Reduced resonances and chatter of front panels;

Well, once the plan is drawn up, you can get to work.

We cut, saw, wind, solder, paint and so on

The first step was to disassemble and clean the front panels. The metal mesh is sanded, treated with a rust converter and painted. After this, the panels were assembled back, and the metal mesh was installed in plastic with sealant to prevent them from rattling. The sealant is not visible from the outside.

Next, all the body joints and holes were carefully coated with construction silicone sealant from the inside. This is done in order to eliminate any whistling from the escaping air. There weren’t really any gaps in the body, but still.

The next step was to glue two spacers from dry pickets with a cross-section of 45x20 mm into the body; they were glued between the front-rear walls and between the left-right walls, and the spacers were also glued together so that a rigid cross was formed. Thus, we increase the rigidity of the case, because the panels here are already quite large, and the wall thickness is only 12 mm. After this, the entire inside of the body is coated with two layers of rubber-bitumen mastic.

The next step was to insert ports with screw terminals for inserting wires into the housing.

To upholster the inside of the body, ordinary batting was purchased from a fabric store, where it was about 6-7 mm thick, so mats were made from batting folded in three layers. These mats were glued to all walls except the front one, using the same rubber-bitumen mastic and additionally secured in the corners with a furniture stapler.

After finishing the work with the body, it's time to work on the electrical part. Firstly, it was necessary to decide what to install to replace the original tweeters. I was unable to find a native HF, but on the Internet they are asking quite a lot for them, from 700 to 1000 rubles for an old HF, I think that’s a lot. In addition, there is a widespread opinion on the Internet that the original 10 GDV-2-16 are not particularly good in general.

After reading the Internet and estimating the budget, as well as the feasibility of purchasing expensive tweeters for these speakers, we chose our 15 GDV-92-16, produced by Novosibirsk NOEMA. In terms of resistance and sensitivity, they are the same as 10 GDV-2-16, and in terms of quality, they say, they are significantly superior to them. By the way, thank you for the prompt delivery and good packaging of the ordered speakers.

While the speakers were traveling through Russian Post, I started reworking the filters. Again, at first I dug through the forums for a very long time, collected opinions, and eventually found a scheme for altering the filters of these speakers, with good reviews and sufficient justification from the author. Below is a filter diagram taken here. Looking ahead a little, I will say that I liked the sound of the speakers with these filters.

New filter 50 AC-106

As you can see, coils with a fairly high inductance are used here at LF and MF. Winding these on “air” is not so easy, because at the same time it must also have low resistance, which means you need to use a thick wire, the dimensions of the coils are not small. Therefore, it was decided to wind the coils on frames with cores made of transformer iron. A plumbing polypropylene pipe with a diameter of 40 mm was taken as a frame; strips of transformer iron, cut from old Soviet transformers, were tightly packed inside. The bass coil is wound with a wire with a diameter of 1.6 mm over varnish, and the midrange coil is wound with a diameter of 1.2 mm over varnish. The HF coils were wound on original frames without cores, with original wire, where it is about 0.6-0.8 mm in varnish. All coils were wound with careful monitoring of the resulting inductance using an LC meter. This made it possible to achieve an almost perfect match of inductance with the circuit.

The capacitors in the filters were left as original MBGO ones, all resistors were ordered new with a power of 35 W, a resistance of 10 Ohms and 3.3 Ohms. 10 Ohm resistors were taken with a reserve and, using a tester, values closest to those indicated in the circuit were selected. All filter wiring is made with a rigid single-core installation wire with a cross-section of 2.5 mm2. This section was chosen not so much from the desire to make the wire as thick as possible, but so that the wire would not dangle and reliable contact pads could be bent from it.

While I was fiddling with the filters, which took more than one day, the speakers arrived. Of course, their dimensions were different from the old ones, so we had to make new podiums for them. Well, after that it came to assembly.

The filters were installed in the housing, of course, they did not fit in the old place, we had to re-drill the holes and lower the filter lower. The top of the filter was covered with batting; it was specially made longer on the back wall.

The bass reflex tubes had to be glued together before installation, as they fell apart into two halves in our hands. They were inserted into the body using sealant and covered with batting.

It came to the speakers. The HF are fixed to the podiums through gaskets. The midrange cups are inserted into the housing using sealant. The glasses themselves are half filled with fluffy cotton wool. The midrange and bass speakers are covered with seals made from the automotive noise-insulating material Splen. When pulling the speaker, it compresses the joint very well. When pressed, the midrange speaker goes inward reluctantly and returns slowly, which indicates the tightness of the structure.

Unfortunately, time has not spared the shiny metal caps on the woofer and midrange speakers; they have peeled off slightly. I had to paint them with acrylic spray paint. I tried to do this as carefully as possible and in as thin a layer as possible.

And to complete the work on the body, the legs were cut out to replace the poor plastic ones. I cut legs with a diameter of 7 cm from a sheet of soft rubber 4 cm thick. And let audiophiles throw rotten eggs at me, but they work no worse than spikes, which I abandoned after much thought.

After assembly, this is what happened:

After that, the entire body was covered with colorless matte varnish. The plastic facing panels were covered from the inside with pieces of STP Aero automotive vibration insulation, this gave them weight and completely removed all the ringing. Madeline strips were glued under the panels to the body; this is a special anti-creaking sealing material, something like impregnated foam rubber. This was done in order to press the panels as tightly as possible to the body.

At this point the work was completed

Based on the listening results, we can say that the speakers began to play much better than before the modification, they became a pleasure to listen to. There will be no comparisons simply because I have nothing to compare with. There are Microlab SOLO2 Mk2 speakers converted into passives. The same tracks from the same amplifier are played much better by the converted Vega, but this is not surprising, the class of these microlabs is not at all high. Comparing Vega with Hifiman HE-400i headphones is at least stupid, these are things of completely different classes and different eras.

The set results have been achieved. I became nostalgic for those same speakers from my childhood, achieved better and more pleasant sound and had a pleasant time with my hobby. Now these speakers are in my home as the main ones, but it is far from a fact that after some time they will not be replaced by something of better quality, and it is quite likely that these could be other old Soviet speakers.

The budget for the entire event did not exceed 5,000 rubles, this included the purchase of speakers, the purchase of speakers and the purchase of some materials. For this money, I think it’s impossible to find something of better quality and better sound. By the way, for the same “Radio Engineering S-90” they ask us for 10,000. They promoted them on the Internet

Thank you all for your attention!

Author: Alexander (Talion_amur), 2017

Based on materials from: geektimes.ru

Types of damage to the speaker system

Various damages and malfunctions may occur in the Vega column. They can be divided into electrical ones that interfere with listening (lack of sound, extraneous sounds in the speakers) and aesthetic ones (damage to the case, fading of paint, chipped front panel grille).

Damage to speakers

- Speaker damage

- Frequency filter fault

- Broken internal speaker wires

- Aging of foam rubber

- Chips on the body

Work plan

After the initial inspection, a rough plan was drawn up:

1. Sealing all seams, joints and holes from the inside of the speakers with sealant; 2. Gluing wooden spacers inside the body according to the front-back and left-right pattern; 3. Treatment of all walls with rubber-bitumen mastic to reduce resonances; 4. Pasting all walls with a layer of batting; 5. Replacement of high-frequency speakers with the production of new podiums for them; 6. Complete rework of filters with changes in the circuit and part ratings; 7. Replacement of all seals under the speakers; 8. Replacement of all wires; 9. Installation of ports with terminals; 10. Washing panels and painting grilles; 11. Reduced resonances and chatter of front panels;

Well, once the plan is drawn up, you can get to work.

Types of damage to speakers

- Diffuser rupture.

Determined visually, there is no point in repairing such a speaker and it is easier to replace it with a similar one.

- Short circuit or break in the voice coil.

It is determined by a multimeter turned on in ohmmeter mode; if there is a break, the device will show an infinitely large resistance, and if it is shorted, its value will be much less than the nominal value. This reel will have to be rewound

- The coil is not centered correctly.

If the coil has come unstuck from the centering washer and is rubbing against the flange, then you need to carefully disassemble the speaker and center it.

- Broken connecting wires.

A common reason for the lack of sound is chafing of the wires from the speaker contacts (lobes) to the coil. If a malfunction of this kind occurs, you should carefully replace it by soldering a similar connection (taking it from an old speaker).

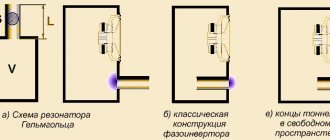

Restoring the filter and internal speaker wiring

If the filter is damaged, one speaker may go completely silent or start working out of its frequency range, this has a detrimental effect on the listening quality. To fix the problem, you will need to remove the back wall of the column and remove the filter. The damaged element (inductor or capacitor) must be replaced.

In some models of Vega speakers, there is no low-pass filter at all, which has a detrimental effect on the depth of sound of the woofer. To eliminate this drawback, you can assemble a simple filter, which will immediately improve the sound quality and increase the service life of the speaker.

When restoring Vega speakers, it is advisable to replace the internal switching and install an amplifier connector.