Hi all! If you have at least a little knowledge of electronics, a computer speaker circuit will not be difficult for you. If you have direct hands, a soldering iron and the necessary components, you can assemble such a device yourself, if you wish.

In this post we will look at the circuit diagram of the simplest speaker for a PC - what such devices consist of and what functions each node performs. Read about how sound speakers work and their functions here.

power unit

Like any electronic device, a computer speaker requires electrical energy to operate. The built-in power supply converts alternating current into direct current, which is necessary for the operation of the device. The power of the power supply depends on the power of the speakers themselves.

There are compact speakers powered by USB. The connector that connects to the corresponding port supplies DC current to the device, so there is no rectifier.

Such speakers can be used not only in conjunction with a computer or laptop, but also with a smartphone or tablet. For power supply, a collapsible charger from a gadget with a built-in USB port is used.

Unit design

Most gas water heaters are instantaneous type. Each instantaneous water heater (gas) has approximately the same operating principle and similar components. The operating principle of an instantaneous gas water heater is quite simple: gas heats cold water from a heat exchanger.

In this case, the unit itself automatically shuts off the gas flow as soon as a decrease in water pressure is detected. This eliminates the possibility of the unit overheating. In addition, using a special sensor, the device monitors gas leakage, completely turning off the column if there is no traction. Thus, the geyser remains safe for owners.

The design of a Neva gas water heater is given as an example.

Device structure from the outside

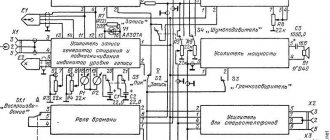

Connecting a gas water heater can be quite confusing. Below is a drawing in which you can see what the gas water heater consists of.

Scheme of operation of the “Neva” model

What is included in the external part of the device:

- Metal casing (No. 1) covering the device.

- A special viewing window (No. 2) located on the facade of the water heater. Through it you can visually monitor what is happening in the column.

- Under the window there are two knobs (valve) of the regulator - one for gas (No. 3), the other for water (No. 4). The operating principle of valves is based on the action of a drive mechanism, which can be either a human hand or an electric drive. Under the influence of force, the valve spindle rotates, which, when rotated, ensures a change in the shut-off element of the valve.

- Between the regulators there is a liquid crystal display (No. 5), on which you can see the current temperature of the supplied water.

- At the bottom of the unit there are pipes responsible for the supply and removal of water, and for the supply of gas. A pipe (No. 6) is installed in the right half of the water heater, into which cold water coming from the water supply is introduced on one side, and on the other side there is a pipe connected (No. 7) that leads warm water out to the consumer.

- A little to the left (No. 8) there is another pipe connected to a gas outlet hose. The hose is connected to the gas line or gas cylinder.

- At the very top of the device (No. 9) there is a flange that connects to the gas exhaust pipe.

- All of the above mechanisms are attached to a special “wall” (No. 10) with two holes for brackets.

REFERENCE: The design of the Neva gas water heater, of course, is not something unique: the design of the Astra water column has a similar structure. Many other models also have a similar structure.

Internal structure of the unit

To inspect the inside of the device, you need to remove the outer casing.

So, what does a gas water heater consist of:

- The water regulator (No. 12) opens the gas when you turn the tap handle. It is connected to the water pipe (No. 6). A (No. 13) rod is attached to the water unit of the column for (No. 13) adjusting the water pressure.

- The cylinder (No. 14), with a small section on the walls, works like a plug, when removed, all the liquid in the heater is urgently drained. This is necessary, for example, if repairs need to be carried out. In addition, this cylinder is equipped with a gas safety valve, which opens when there is a serious change in pressure in the line.

- In the central part there is a control unit for the gas water heater (No. 16), which is necessary to control the pressure temperature. There are many wires coming from it that connect various sensors and other internal mechanisms to the unit.

- As with the water regulator, a rod with a handle is removed from the gas regulator (No. 17). (No. 18). The gas unit leads gas pipes to the burners.

- Directly between the gas pipe and the tap to regulate the flow of gas there is an electromagnetic valve for the gas water heater (No. 19). It serves to transport gas to the gas unit. In addition, a handle is attached to it that controls the power level and ignition of the device.

- Located slightly higher (No. 20) is a manifold, which is connected to the gas block through a flange pipe. It is attached to the speaker body with two screws (No. 21). On the manifold you can find special nozzles through which the gas flows directly to the burner, consisting of ten rows (No. 22). There is also a spark plug attached to the manifold, which forms a spark to ignite the burner and a flame sensor (No. 24)

- The principle of operation of a battery-powered geyser is that in the central part of the block there is a switch (No. 15), which is acted upon by a special pusher connected to a rod. It is the switch that “releases” electricity from the battery in the gas water heater. First it goes to the control section, and then to the igniter, where a spark is formed.

- Above the collector there is a copper heat exchange module (No. 25), attached to the housing with two screws (No. 28). It is this that transfers heat to cold water. On the right side of the exchanger there is a water reducer for the gas water heater (No. 26), and on the left there is a pipe for outputting warm water (No. 27). The drainage pipe is equipped with two safety sensors: one (29) is for protection against overheating, the other serves as a thermometer that transmits information through wires directly to the LCD display.

- At the top of the column there is (No. 31) a system for removing burnt gas. Through many jumpers, waste combustion products are discharged directly into the chimney channel. To the left is (No. 32) the traction sensor. The principle of operation of the traction sensor is simple: it serves as a fuse that turns off the device in the absence of traction. The draft sensor is connected to the overheating sensor (No. 29), while the operating principle of the draft sensor is not much different from the operation of the overheating sensor, it’s just that the first protects the system from gas leakage, and the second directly from overheating.

- At the very bottom you can see a special block (No. 34), where there are two batteries. The principle of operation of a battery-powered gas water heater is based on complete automation of ignition. The installed batteries provide a spark for ignition and ensure autonomous operation of the unit. The only downside is that the batteries don't last long. Ignition of older speakers is carried out manually.

- There are holes on both sides of the cabinet (#33) for screws that secure the cabinet to the wall.

REFERENCE: The design of the Oasis speaker is practically no different from the above. The gas and water blocks of the Oasis gas water heater have a similar structure, the only difference is that the Oasis has a special “Winter and Summer” switch on the front panel, which in the summer turns off half of the operating burners to save money. If your gas water heater does not work at all in the summer, then you can turn off the gas supply completely.

Audio input

All computer speakers are connected to the signal source via a 3.5 mm jack - this is the port built into the sound card on the motherboard and in most external sound cards.

Of course, there are audio speakers with specific ports, so the equipment needs to be connected accordingly. The most common type of interface for professional speaker systems is a 6.3 mm jack.

The signal transmitting cable can be soldered “tightly” to the audio signal amplifier or connected separately - usually using RCA plugs.

The speakers are connected to each other either using the same connectors, or with a regular wire with bare ends, which is fixed using special latches. In addition, the connecting cables can also be “tightly” attached to the body and be permanent.

Complex and unusual forms of AS

Rice.

6. Complex and unusual shapes of speakers Having deeply and almost thoroughly studied the capabilities of standard types of acoustic design and having tried many different materials from which certain sound systems are made, true lovers of high-quality sound move on. The focus is not only on unusual forms of speakers, but also on their particularly complex modifications.

The inventors of unusual and complex acoustic systems go to great lengths. The laws of physics cannot be fooled, so the desire for ideal sound leads creators to very unexpected forms of speakers.

Electrostatic interaction

The principle of electrostatic interaction formed the basis for experiments and development of non-standard emitters of the same name - electrostatic loudspeakers. The design of such a speaker is indeed quite unusual.

An ultra-light membrane with a conductive coating is stretched between two stator grids. The membrane is ultra-thin (10 times thinner than a human hair). The vibrations of the membrane are excited by an amplified sound signal arriving at the stator grids. The result is the reproduction of very detailed and transparent sound with a very low non-linear distortion coefficient (up to only 0.05%).

Among electrostatic loudspeakers, there are modifications with a curved panel, spherical, and with plates with a curved surface. There are products with a triangular emitter and a segmented stator. And there are designs with an electrostatic panel with gas filling. More information about these variations and the advantages and disadvantages of electrostatic loudspeakers can be found in the article “Electrostatic loudspeaker with a wide polar pattern.”

Modern speaker systems

Today, the range of modern acoustic systems offered is extremely rich. Dozens of speaker formats can satisfy the needs of even the most sophisticated lover of high-quality sound.

The speakers are presented in portable and household configurations, studio and concert, Hi-Fi and wireless, broadcast. Each of the presented options is intended for its own sphere and, accordingly, has certain characteristics.

So household acoustics are inexpensive, low-power, broadband speakers with stereo sound. Sufficient for listening to music at home.

Studio and concert speakers are much more professional designs. Such speakers are used by specialists when working in audio studios. The capabilities of such systems are much wider, the sound quality is much better.

Reproducing sound in industrial and other special premises to ensure proper notification is the prerogative of broadcast acoustic systems .

A separate and very popular category are portable and wireless speakers . Using the well-known bluetooth channel, speakers can be not only compact in size, but also wireless. Stylish design (as a rule, the type of speaker design is a closed box) and a powerful battery on board allow such speakers to organically fit into any style, making them the highlight of the interior.

For example, the JBL Charge 4 wireless speaker system is small in size, has good sound, and is popular not only among young people. It has an acoustic design with a passive radiator, as can be seen from the following video.

Also, such microsystems are very popular among athletes and other lovers of mobile life. A headset with decent sound quality is always at hand, which is extremely convenient in today's dynamic world.

Contra-aperture audio systems

Another rather unusual acoustic system is counter-aperture speakers . This is a kind of omnidirectional acoustics that evenly fills the space with sound waves. This effect is achieved by two speakers located opposite each other strictly in a vertical plane.

Absolutely synchronously colliding sound waves accumulate a resulting wave propagating in all directions. There will be no sound holes at all points in the room, just one continuous comfortable listening area.

Vibrating speakers

For this speaker design to function, it is enough to have any hard surface at hand: a window, an ordinary table, or even a juice or milk box. By transmitting vibrations to a solid surface, such a device turns it into one continuous diffuser.

Of course, the sound quality of such an acoustic system will be poor, but such products have also found their use at various exhibitions, museums and restaurants. Attached to a large, flat display case or stand, the device will turn it into an invisible loudspeaker.

360° Loudspeaker

The Omnisono all-encompassing loudspeaker Such a speaker is considered to be one whose dimensions are disproportionately small compared to the length of the sound wave it excites. If we take the low frequency sector in the operating range, then all the speakers will be point emitters for them. However, their directionality becomes more acute as the signal frequency increases, when the length of the emitted sound wave and the dimensions of the speaker become commensurate.

Acoustic Rubik

Well, in conclusion, we will give an example of a true fan of acoustic science, who made a subwoofer not just as a high-quality acoustic system. As a result of painstaking work, a 15″ subwoofer was created in the shape of a real... Rubik's cube, a giant cube.

The acoustic system turned out to be not only spectacular in appearance. This is a true sealed Sub system with a large speaker and an amplifier built into the cabinet. Vibration is minimized by the significant weight of the entire structure with accurate calculation of the internal volume and communications wiring. For a detailed photo report with explanation, see the article “Subwoofer in the style of a Rubik's cube.”

Signal amplifier

This node is present only in active acoustic copies - passive ones are connected to an external amplifier. The vast majority of modern computer options, including 7.1 format with a subwoofer and six satellites, are also active.

The amplifier's task is to make the weak signal supplied from the sound card powerful enough for the speakers used in the speaker system. In addition, the signal amplifier has another role - it filters the incoming signal, removing unnecessary noise, and equalizes it across the frequency range.

As a rule, there are controls on the front panel of the signal amplifier - at least a power button, volume and bass controls.

Circuit of the simplest amplifier for a speaker system:

Edge corrugation

This element is also called a “collar”. This is a plastic or rubber edging that describes the electrodynamic mechanism over the entire area. Sometimes natural fabrics with a special vibration-attenuating coating are used as the main material. Corrugations are divided not only by the type of material from which they are made, but also by shape. The most popular subtype is toroidal profiles.

A “collar” is subject to a number of requirements, compliance with which indicates its high quality. The first requirement is high flexibility. The resonant frequency of the corrugation should be low. The second requirement is that the corrugation must be well fixed and provide only one type of vibration - parallel. The third requirement is reliability. The “collar” must respond adequately to temperature changes and “normal” wear, maintaining its shape for a long time.

To achieve the best sound balance, rubber corrugations are used in low-frequency speakers, and paper corrugations are used in high-frequency speakers.

The main radiating object in electrodynamics is the diffuser. The speaker diffuser is a kind of piston that moves in a straight line up and down and maintains the amplitude-frequency response (hereinafter referred to as the frequency response) in a linear form. As the oscillation frequency increases, the diffuser begins to bend. Because of this, so-called standing waves appear, which, in turn, lead to dips and rises in the frequency response graph. To minimize this effect, designers use stiffer diffusers made from lower density materials. If the speaker size is 12 inches, then the frequency range in it will vary within 1 kilohertz for low frequencies, 3 kilohertz for mid frequencies and 16 kilohertz for high frequencies.

- Diffusers can be hard. They are made of ceramic or aluminum. Such products provide the lowest level of sound distortion. Speakers with hard cones are much more expensive than their analogues.

- Soft diffusers are made of polypropylene. Such samples provide the softest and warmest sound due to the absorption of waves by soft material.

- Semi-rigid diffusers are a compromise option. They are made from Kevlar or fiberglass. The distortion caused by such a diffuser is higher than that of hard diffusers, but lower than that of soft ones.

The cap is a shell made of synthetic or fabric, the main function of which is to protect the speakers from dust. In addition, the cap plays an important role in shaping a certain sound. In particular, when reproducing mid frequencies. For the purpose of the most rigid fastening, the caps are made round in shape, giving them a slight bend. As you probably already understood, the variety of materials is precisely related to achieving a certain sound. Fabrics with various impregnations, films, cellulose compositions and even metal meshes are used. The latter, in turn, also serve as a radiator. An aluminum or metal mesh conducts excess heat away from the coil.

Sometimes it is also called a "spider". This is a heavy part located between the speaker cone and its body. The puck's job is to maintain a stable resonance for the low-frequency speakers. This is especially important if there are sudden temperature changes in the room. The washer fixes the position of the coil and the entire moving system, and also closes the magnetic gap, preventing dust from entering it. Classic washers are a round corrugated disk. More modern options look a little different. Some manufacturers deliberately change the shape of the corrugations in such a way as to increase frequency linearity and stabilize the shape of the washer. This design greatly affects the price of the speaker. Washers are made from nylon, calico or copper. The last option, as in the case of the cap, serves as a mini-radiator.

Speakers

Dynamic drivers are the core and main component of any audio system. A modern standard mid-price speaker is equipped inside with at least two speakers - for low and high frequencies, respectively.

This is due to the fact that different speakers do not equally reproduce sound of different frequencies - the lower it is, the larger the diameter of the speaker should be. In systems with a subwoofer, the low-frequency emitter is placed in a separate housing so that it does not interfere with the sound of the others.

Today there are speaker systems on the market with two types of speakers. The first type uses a cone emitter, the so-called diffuser, the operating principle of which is based on the interaction of the magnetic field of an electric coil with the field of a permanent magnet.

The output is powerful sound and rich bass.

The second type of speaker uses a flat membrane instead of a diffuser. Such emitters significantly lose in power, but have very compact dimensions. This makes them very effective in creating portable speaker systems.

They are also used in budget acoustics in conjunction with a subwoofer.

How speakers are made

Thanks to modern technologies, the factory currently handles most of the production. Thus, a special machine produces the necessary parts for the body, fastens the corners and creates blanks of even the most complex shapes. Next, workers grind the surfaces themselves. After which the products are sent to the warehouse while the electronics are born. Employees with certain experience assemble and reproduce the installation manually. Next, the speakers are installed. Finally, each invention is tested. This is done by comparison with the standard.

REFERENCE. And under equal conditions. If the result remains positive, then the devices are taken to the finished goods warehouse, where they are directly packaged.

Subscribe to our Social networks

Principle of operation

To correctly understand the principle of operation of a gas water heater, you must first understand how its security system works.

If the device is turned off, the control unit of the geyser stops receiving power, because The electrical circuit in the switch is broken. This occurs due to the fact that the pushing mechanism presses the switch plate and keeps it off.

The electromagnetic valve on the gas column is also in a closed state and blocks the gas flow from the inlet pipe, because No power is supplied to it either. However, not only does it prevent the passage of gas: the spring valve located in the gas module is also turned off, and the outflow of gas into the manifold is completely closed.

The main element of the water reducer of a gas water heater is a two-chamber module with a bending membrane, popularly called a “frog”. These modules communicate with each other using the appropriate channel. If the water supply is turned off, the pressure in the chambers is equalized.