The speaker system is an important component of any audio equipment. Its main task is to process the electrical impulse, converting it into a sound signal. The requirements for such equipment are approximately the same. It must have sufficient power to reproduce frequencies accessible to the human ear without distorting the sound. Of course, the sound quality is primarily affected by speakers and various filters. But even without a high-quality case it is impossible to imagine first-class equipment. For this reason, some enthusiasts may have the idea of making their own speaker cabinets from plywood.

Such a desire may appear in several cases:

- I’m not happy with the sound of the old system, but I don’t want to buy an expensive installation;

- I want to experiment with sound in order to achieve reliable transmission of music, voices or various audio effects;

- the idea arose to make an extraordinary and one-of-a-kind thing that would not only be useful, but also become a decorative element that could diversify the interior.

The most interesting videos on Youtube

Hello, friends!

While drinking a two-liter bottle of beer, I made a bet with a friend that I could make a speaker from this very bottle.

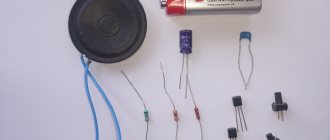

Just the day before, I was winding flat coils for another project, and on the table at that time there were magnets bought on Ali Express. In general, the idea was in the air.

You can now see and hear how it all ended if you watch the video. For the rest, I wrote short comments to the pictures illustrating the process of making and assembling the loudspeaker.

Making your own speakers

Using this principle, you can easily assemble speakers with your own hands from various available materials. Interesting results are obtained from plastic bottles that use a neck and a conical top part. This is an almost finished diffuser. Small speakers can be made from paper cups. The main thing is not to make the winding resistance too small. This can damage the amplifier's final stage. Interesting results are obtained using a flat coil, the turns of which are glued to a sheet of thick paper.

If you don't want to read boring text, watch the video.

To wind a flat coil you will need to make a simple device.

The glue is pre-cured by heating the coil with an electric current, just as is done when repairing speakers. But, however, when using deaf cheeks, this takes about a day.

PTFE gaskets allow you to separate the coil from the device.

Additional sizing of the coil increases reliability.

After the glue has completely cured, the coil becomes deformed and must be straightened using a hair dryer and a press. Adhesives "BF-2" and "BF-4" become elastic at temperatures above 150°C without deteriorating properties

Getting a straight edge when cutting a PET bottle with scissors turned out to be more difficult than heating a piece of nichrome wire.

This is the process of giving the final shape to the body of the future speaker.

The hole will be needed to attach the magnet.

The speaker uses several neodymium magnets with holes, ordered from Ali Express. The distance between the edge of the magnet and the top edge of the speaker housing can be adjusted using washers.

The diffuser is made of some kind of cardboard packaging.

To assemble the moving system, double-sided tape was used.

The idea of using plastic film as a speaker suspension was inspired by the design of the isodynamic head.

This is what the membrane of a factory isodynamic speaker looks like.

Attaching the diffuser to the membrane.

Attaching the coil to the diffuser.

A piece of writing paper increases the reliability of the moving system.

Installing the moving system into the speaker housing.

Installing a speaker in an acoustic design.

I have long wanted to show how you can tin an enameled wire using an aspirin tablet.

Be careful and do not inhale these toxic fumes under any circumstances!

All that remains is to add damping filler and connect the coil leads to the cable.

| This movie requires Flash Player 9 |

This is what happened.

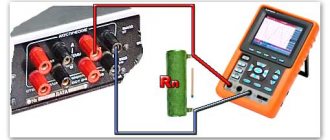

Talking bottle tests.

Of course, the subwoofer did not work out of a bottle, and if you watch the associated video, you can hear the distortion that appears when the level of low frequencies increases. However, the loudspeaker still produces articulate sounds, and they are definitely no worse than those produced by my first plastic computer speakers.

Pay attention to other popular topics, links to which are at the end of the article.

Creative success to you, friends!

Cookware

The simplest DIY smartphone speaker can be found in any kitchen and is a suitable-sized bowl, vase or cup. Do not underestimate the size and material of the utensil for the sound of the device. Products made of bamboo, plastic, glass or ceramics, with different thicknesses and sizes, give such different audio effects that any built-in software equalizer takes a break. By experimenting with different containers, you can find the sound that suits you best. As for the gain, it is much better when the speaker is pointed towards the bottom of the bowl.

Magazine

No less interesting results can be obtained from using a magazine rolled into a tube. Secure the structure with rubber bands, paper clips or glue, then cut a slot for the phone approximately in the middle. Insert it so that the phone's speaker is inside the magazine. The sounds produced by such a device cannot boast of excessive volume, but they acquire some volume and even nobility, thanks to the muting of too high notes emitted by the phone's beeper.

Plastic is cheap, but resonates

Plastic, which also includes composites, is often used in the production of budget speakers, those that are still Chinese. The plastic body is lightweight, significantly expands the possibilities of designers; thanks to casting, almost any shape can be realized.

Different types of plastics differ greatly in their acoustic properties.

Plastic is very popular when creating wearable speaker systems that operate via Bluetooth, such as JBL. At the same time, manufacturers managed to solve the problem of resonance.

Wireless speaker Philips SB500A

Just a few years ago, plastic was not very popular in the production of high-quality home acoustics.

But at the moment it is in demand for professional samples, where low weight and mobility of the device are important.

Chips packaging

This design is unstable, so you will have to take care to fix it. Despite its appearance, this device has good sound amplification abilities and good quality. You can also change it significantly by trying different sound tube fillers, such as toilet paper.

Taking as a basis the proposed methods of amplifying sound vibrations and supplementing them with your own inventions, you can not only find your own unique telephone speaker design, but also have fun. Experiment, invent, share your finds in the comments!

Photo: Shutterstock

Preparing tools

So, during the work we will need the following materials and tools:

- screwdriver;

- sheet of chipboard or MDF (for making the speaker system housing);

- marker;

- jigsaw;

- 400 W PC power supply;

- radio;

- Bulgarian;

- a pair of acoustic speakers;

- furniture screws and self-tapping screws;

- sealant (it is best to use silicone based);

- voltmeter and glue.

Before assembling the speaker system, first check the operation of the radio and find out whether it can be powered or not. It is also necessary to test the speakers for sound quality. After this, you can safely begin manufacturing the housing and other elements of the speaker system.

What materials do we need to assemble the subwoofer?

The material for making the subwoofer box must be durable, dense and well insulating sound. Multilayer plywood or chipboard is perfect for this. The main advantages of these materials are their affordable price and ease of processing. They are quite durable and provide good sound insulation. We will make a subwoofer from 30 mm thick multilayer plywood.

To make a subwoofer box we will need:

- Wood screws (approximately 50-55 mm, 100 pieces)

- Soundproofing material (Shumka)

- Drill and screwdriver (or screwdriver)

- Jigsaw

- Liquid Nails

- Sealant

- PVA glue

- Carpet, approximately 3 meters

- Klemnik

Column device

The simplest floor-standing speaker is a box or box in which one full-range or several narrow-band speakers are located. One speaker will not need a crossover filter. Two or more are consistent across the spectrum (subrange) of audio frequencies. To improve the low-frequency response, the speaker is equipped with a bass reflex - a channel with a circular cross-section into which the lowest frequencies are reflected.

One of the stereo speakers is active (it contains an amplifier, power supply and output for another speaker). The second is passive (slave). Instead of a detachable cord, wireless communication via Bluetooth is organized between the speakers - this allows you to take the speaker to any corner of the room without running a wire between it and the second one.

Portable speakers, in addition to Bluetooth communication, are equipped with a device for reading data from flash drives and memory cards, a simple FM receiver with a scanning setting, an LED strip with color music (or a matrix with a running line) and a number of other functions. They are often equipped with a carrying handle.