Hello dear readers of our favorite portal Datagor.ru!

I haven't been heard from for about a year. During this time, I managed to become a father and the time for amateur radio suddenly became less. But I did not abandon my radio-electronic research, but brought to life one of my most ambitious projects in the field of ULF. There was a lot of time for thinking and little time for practical implementation. The project was carried out slowly, so the quality of the details was as high as possible. I didn’t spare money to achieve the result I needed and didn’t make compromises to reduce the cost or simplify the design.

"BRASS"

- because everything lives in a body made of polished brass 1.5 mm thick and varnished. For other funny translation meanings, see the English dictionary.

The project includes:

— The main stereo ULF block according to the Nobu Shishido circuit with a push-pull output to 6P3S. — Tube RIAA stereo vinyl corrector for 6N2P. — MP3 unit operating via USB with flash memory. — Remote control of the MP3 unit. — Remote control of the main amplifier volume potentiometer using a brush motor.

In the first part of a series of articles, I will talk about assembling the main amplifier and corrector circuit for connecting a vinyl player.

↑ Selecting an ultrasonic frequency circuit

Choosing the circuit for the main ULF block was long and painful.

I looked at a lot of diagrams, both on our Datagor and on third-party sites. I even listened to samples of homemade amplifiers on Youtube (which, by the way, predictably turned out to be useless, since the filming does not convey the distinctive features of the circuits in terms of sound). The choice was between a push-pull amplifier based on 6P3S and 6S33S. I have already heard both lamps in push-pull operation. I have a 6P3S guitar combo amplifier and the sound of this lamp is pleasant to me. I heard 6С33С many times from an audiophile friend who wound the output transformers with the overall power of iron slightly lower than the dissipation power of the lamps in push-pull operation, which could not but affect the sound, which, to my ear, seemed somewhat hysterical, thereby distorting my idea of this lamp.

The only option left is the two-stroke 6P3S. Among the articles on Datagor.ru, I liked the implementation of comrade Mikhail (Lektor) with his modification “Push-pull tube amplifier on 6P3S based on Nobu Shishido.” Having studied the original source and its modification, I decided to test everything in practice and choose a sound more favorable to my hearing.

I definitely like the idea of a higher current driver. The sound of the pentode switching seemed unusual to me, because I was used to the triode sound.

Stabilizing the grid at a relatively high voltage using a gas-discharge zener diode SG16P, in my opinion, does not make any changes to the sound - whatever I listened to in this version, from pop to metal.

Feedback - I didn’t even try here, because I am an ardent fighter against feedback in tube amplifiers.

↑ I'll scrape the bottom of the barrel and drop the droppings in the barns

As I have said more than once, most of my projects start with the body. I rummaged through the closets in the office and found a box with various electrical junk that was left over from last year's office renovation. From it was taken an iron box from an old alarm system, a 12 V electronic transformer for powering halogen lamps, four sockets for lighting lamps with an E14 base and a pair of large real 220/12 V iron transformers, also used to power low-voltage light bulbs.

Then the idea was born to make an amplifier, ignoring the established canons of the Hi-End tube, using the goodness found to the maximum. While she is thinking about the future scheme in her head, she does not give rest to her hands.

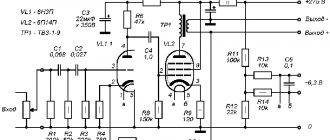

↑ Scheme from my project

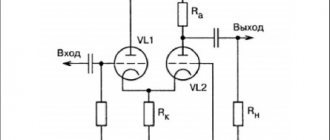

As a result, I assembled a hybrid circuit with a higher current driver relative to the original and the original terminal, but without feedback.

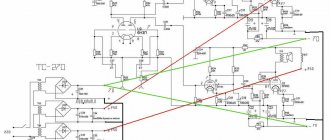

In the diagram you can see the vinyl corrector block, which I will talk about a little later.

The high-resolution diagram is in the archive below. Resistors from 0.5 to 2 Watt MF 5%, 5 Watt Chinese ceramic. I would like to note that in my version of the driver, anode resistors (R30 in the diagram) should be used with a power of 5 Watts (2 Watt resistors will turn black). I used film capacitors for all interstage capacitors for a voltage of 400 Volts.

Parts List

The table below presents a list of parts required to assemble one monoblock tube amplifier. For the stereo version you will need 2 times more details.

| № | Name | Quantity |

| 1 | Lamp 6P6S | 2 |

| 2 | Lamp 6N8S | 1 |

| 3 | Lamp panel PL8-2P | 3 |

| 4 | Transformer TAN3-127/220-50 | 2 |

| 5 | Throttle D21N | 1 |

| 6 | Capacitor K71-7 0.5 µF | 4 |

| 7 | Capacitor 100 uF x 400V | 3 |

| 8 | Capacitor 100 uF x 25V | 1 |

| 9 | Resistor 39 kOhm 0.5 W | 2 |

| 10 | Resistor 270 kOhm 0.5 W | 2 |

| 11 | Resistor 430 Ohm 0.5 W | 1 |

| 12 | Resistor 3.9 kOhm 0.5 W | 1 |

| 13 | Resistor 470 kOhm 0.5 W | 2 |

| 14 | Resistor 1 kOhm 0.5 W | 2 |

| 15 | Resistor 200 Ohm 2 W | 2 |

| 16 | Resistor 220 Ohm 2 W | 1 |

| 17 | Resistor 2.2 kOhm 0.5 W | 1 |

| 18 | Resistor 200 Ohm 0.5 W | 2 |

| 19 | Diode bridge RS206 | 1 |

| 20 | Tumblr | 1 |

| 21 | Fuse holder | 1 |

| 22 | Fuse 0.5 A | 1 |

| 23 | Network Europlug | 1 |

| 24 | RCA connector | 1 |

| 25 | Speaker jack | 2 |

| 26 | Aluminum housing Gainta B019BK | 1 |

| 27 | Aluminum housing Gainta B039BK | 1 |

| 27 | Instrument leg | 4 |

↑ Description of catering

I’ll start the description of the circuit with the main one – the power supply, or rather three power supplies.

The main problem was to find a network transformer with a load capacity of at least 0.38 A at a voltage of 300-350 V on the secondary windings.

The solution was to purchase three TAN-55 transformers from the local radio market and connect the secondary windings in series.

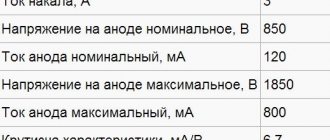

Conclusions TAN-55

The photo also shows a 220/12V step-down transformer with a load capacity of 1A, which was introduced into the design later, during the development of control and lighting.

I used a two-level filter rectifier.

At the first stage, a field-effect transistor filter, or an electronic choke (whichever is more convenient) proposed by Loki and TANk, and at the second stage a regular P-filter (capacitance + choke + capacitance). I didn’t skimp on copper, so I used a pair of D47 chokes.

There is a divider at the output to remove the voltage of about 40-60V and apply it to the middle filament point to close the parasitic filament-grid diode of the lamp.

The power supply is made on a separate board as a monoblock with two-stage filter elements and a 6P3S lamp bias rectifier.

I used UF5408 ultrafast diodes for the anode supply, and BYV26C schottky diodes for the bias. For ease of adjustment, I installed trimming resistors at the top edge of the board. Each amplification channel has its own power board.

Hedgehog-type transistor IRF740 radiator 54x32x25mm. When testing the maximum power of the amplifier, it heated up to 37-39 degrees.

Input electrolytic tanks must be 450V. If you use it at 400 V and run it without load, it will definitely be “rose”. I took film capacitors with a reserve of 630 V.

To power the vinyl corrector

used one common stage with a field-effect transistor filter and a parallel P-filter circuit.

The current consumption of the anode of the 6N2P lamp is less than 10 mA, so I decided not to make a separate field-effect transistor filter for each channel.

The filament of the vinyl corrector lamps is powered by direct current using the same P-filter, which was not my maximalist whim, but a necessity.

The background in the incandescent circuit was overcome only by introducing a choke (which I wound with my own 0.35 wire on the iron from the D232 inductor) into the circuit. Vinyl corrector power supply

made on a separate board.

I decided to combine the filament rectifier on the board with a remote control circuit and the second arm of the high voltage P-filter.

↑ Results and reflections

And it turned out surprisingly well.

With an output power of 5 W, the reproducible frequency band is from 15 to 24,000 Hz. Very soft and deep low frequencies. Clear and transparent upper half of the audio range. Very good detail. There is no background in the columns. In fact, it exists, but at a frequency of 50 kHz our ears cannot hear it and it is not reproduced by speakers. It was necessary to introduce elements C1, C2, C8 into the circuit (in red in the diagram) to limit the RF gain, since interference with a frequency of 40-60 kHz from Tashibra is very strong and the oscilloscope sees them well. Powering the lamp filaments with high-frequency alternating current had an effect.

Without any changes in the circuit, the amplifier can be connected to a conventional 50 Hz power transformer that produces the necessary voltages and currents. For example, to TAN-104. In this case, the capacitors marked in red must be removed from the circuit. The band of reproduced frequencies in the HF region will then expand to 50-60 kHz.

At the output, you can use large, beautiful lamps such as 6N5S, 6N13S, one per channel, or even 6S41S. You just need to take into account the increased power consumption. With such tubes, the amplifier will work well with a mahogany body and designer incandescent lamps. Then in the evenings the amplifier will delight you not only with pleasant music, but with subdued soft light, acting as a night light in the living room or bedroom. Here's Chandelier for you.

After listening to this amplifier for several days, I began to seriously think about its more thorough and beautiful implementation.

Thank you for your attention!

↑ Settings for the balance of the arms and anode current of the output stages

As I already said, the amplifier is assembled according to the Nobu Shishido circuit, which many have seen and perhaps heard more than once. I want to dwell on the settings for the balance of the arms and the anode current of the output stages.

Due to the fact that the phase inverter arms are unbalanced, load resistors R34 and R35 have different values - 24K and 27K, respectively.

To establish symmetry, you need to apply a signal to the amplifier input (in my case it is 1 kHz from the generator) and use a 1 µF 400 V film capacitance to measure the voltage level on resistor R35 with a tester, then discharge the capacitor and perform the measurement on R34.

Then take additional resistors from 100 Ohms to 3 kOhms and connect them in series with resistor R34, each time measuring the voltage values, first discharging the capacitor. On my board, resistor R34 is composite for ease of setup.

Next, you need to set the anode currents of each 6P3S lamp; for this, by adjusting the voltage with construction resistors on the power boards, we achieve a voltage drop across the cathode resistors of +0.05V.

↑ Fighting the background

I assumed that there should be no background, because I made the printed circuit board according to all the rules for wiring the ground in tube amplifiers.

But there was a background. Comrades from our forum gave a lot of advice on how to eliminate it, but the result was still the same. The solution was the article “On the installation of signal circuits in a tube amplifier,” which was posted by Igor Kotov several years ago. (I highly recommend reading it and bookmarking it - it will save you a lot of nerve cells). I performed the so-called double shielding of the interconnect cable and the background disappeared. The problem was interference in a fairly reliable (as I myself assumed) cable from the computer to the amplifier.

Frame

The case is the most important part of a tube amplifier, since it acts as a chassis on which transformers, lamps, capacitors, and connectors are mounted. Making a beautiful case with your own hands is quite a difficult task, so the choice fell on the use of universal cases. Thus, the basis for the chassis and casings of the transformers were aluminum alloy housings from the Taiwanese company Gainta. The advantage of these cases is good heat distribution, ease of processing, and noble appearance.

Structurally, the amplifier is made in the form of 2 monoblocks with an open design. For the chassis, B019BK housings with dimensions of 275x175x65 were chosen, on which output and power transformers, lamp sockets, and connectors are mounted. And the upper parts from B039BK housings with dimensions 171x121x106 were used as casings for transformers. The open design in combination with the aluminum housing ensures good heat dissipation from the lamps, which heat up significantly during operation.

Fig.1. Housings B019BK and B039BK - the basis of the tube amplifier chassis

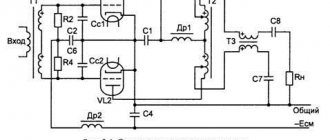

↑ Vinyl corrector

The amplifier finished, but it seemed to me that this was too little and I looked towards my converted Melodiya-103 vinyl record player.

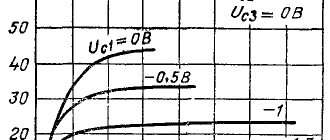

Why not take the signal directly from the pickup rather than stripping it from a brick and mortar preamp? This is how the idea was born to integrate a 6N2P vinyl corrector into the main board. I decided to make the stereo vinyl corrector using 6N2P double triodes, since I had long studied its sound qualities (I didn’t want to experiment). I chose the following scheme

You can adjust the sound of mid and high frequencies using capacitors C20 (from 1n to 470n) and C21 (from 1000 pF to 3400 pF) by adjusting the frequency divider. The output capacitor (necessarily film, audiophile type WIMA MKP10, etc.) has a maximum capacity, but within reason, I soldered 10 μF.

The corrector worked perfectly, but again the background was cut through, which was eliminated by powering the lamps with direct current using a P-filter. The inductor was wound with a 0.35 wire specifically for incandescence on miniature iron from the D232 inductor. It turned out to have an inductance of 0.3H and a resistance of 2 Ohms.

The corrector and amplifier boards are combined, see attached archive.

I would also like to say something about the lamp sockets and their mounting. GZC9-Y-1 sockets were used for finger lamps, and GZC8-1 sockets for octal lamps. They were installed from the side of the tracks, for which all the contacts on the board were mirrored.

↑ Saw, Shura, cut. Step drill and dies for punching holes - in capable hands

The iron box that came into my hands had to be turned into a tube amplifier housing.

And for this you need to make quite a lot of different holes in it. For input and output connectors, for lamp panels, for switches and regulators, etc. Making neat, large-diameter holes in thin material is not so easy. I've tried a lot of different methods in the past and eventually settled on a specific set of tools.

I make small holes, up to about 15 mm in diameter, with a step drill.

Set of 3 step bits from 4 to 32 mm in a case. We take it to Ali along with the case!

I almost always have such a drill in the drill chuck. Comfortable! Without changing the drill, you can quickly make any hole with a diameter from 4 to 20 mm.

Making large holes for lamp panels with such drills is not very convenient. Large diameters require a drill with powerful torque, and at the slightest misalignment the drill jams. For holes larger than 20 mm, I use a manual hole punch.

Everything is done simply and quickly. Insert a bolt with a matrix into a hole with a diameter of 10 mm. We screw the punch nut on the other side and make 3-4 turns with a wrench.

A smooth hole with edges that do not require additional processing is ready. This simple device easily copes with steel sheets up to 3 mm thick, aluminum and fiberglass up to 4 mm thick.

After 10 minutes you can already attach the lamp panels to the body.